thereby moving the control rack inward. To decrease

upward when the screwdriver is removed. If it does not

fuel injection, loosen the inner adjusting screw slightly

return to its original position, it is too loose. If the rack

and tighten the outer screw, which moves the control

becomes tight before the full travel, it is too tight. In

rack outward. In making these operating adjustments,

either case, readjust to obtain the proper feel.

never turn the adjusting screws more than one-fourth

Once the rack is adjusted for the rear injector, begin

turn at a time. If one injector is adjusted too far out of

adjusting the next injector forward. Once it is adjusted,

line with the others, it will prevent the full travel of the

go back to the last injector and check it again. Continue

racks and reduce the maximum power of the engine.

working forward using this method of rechecking the

Do not attempt to obtain a smooth running engine

previously adjusted injectors until all are properly set.

by changing control-rack settings without first timing

Lastly, check the rack for free movement from mini-

and equalizing injection in the recommended manner.

mum speed position through maximum speed position

without an increase in effort toward the end of the

TROUBLESHOOTING

travel.

When calibrated injectors are used, the manufac-

Diesel engines have higher compression pressures,

turer's method of equalizing racks should be followed.

compression temperatures, and compression ratios than

It may be necessary to make these adjustments several

gasoline engines; therefore, diesel engines must be of a

times before the engine runs just right.

heavier and stronger construction. Even with stronger

Sometimes smoother engine operation can be

built engines, good servicing, and maintenance, the

obtained by making slight changes to the equalizing

diesel engine develops malfunctions. When these mal-

adjustments after the engine is warmed to operating

functions occur, troubleshooting must be performed to

temperatures (above 140F). For example, one cylinder

locate the cause so corrective action can be taken to get

may not be carrying its share of the load as indicated by

the engine back to its top performance.

a comparatively cooler cylinder. Its control rack,

Some of the test equipment and troubleshooting

therefore, should be adjusted for more fuel. A slight

practices and procedures used on gasoline engines may

knocking noise from another cylinder would indicate

also be used on diesel engines, but some of the systems

an adjustment for a slightly smaller amount of fuel.

require special test equipment and different trouble-

To increase the amount of fuel injected, loosen the

shooting practices and procedures. Table 4-1 lists a few

outer adjusting screw and tighten the inner screw,

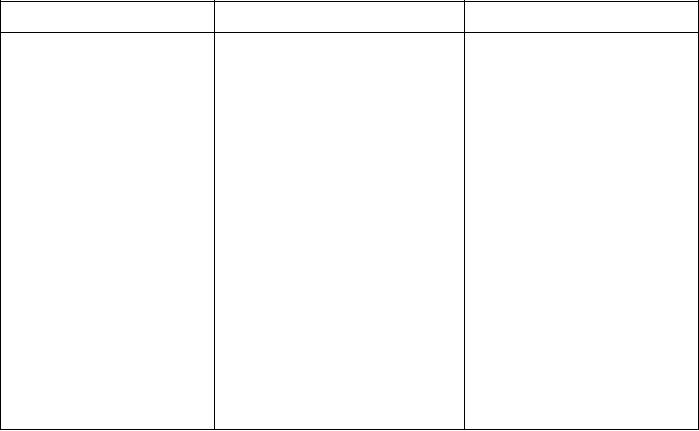

Table 4-1.--Diesel Engine Troubleshooting Chart

TROUBLE

PROBABLE CAUSE

REMEDY

ENGINE STARTING

Engine does not rotate.

Starter/transmission binding.

Repair starter or transmission.

Engine seized.

Replace engine. (Refer to QEC in-

structions.)

Starting motor does not crank Batteries discharged.

Test battery cells. Service or re-

the engine.

place as required.

Loose or corroded electrical con-

Clean dirty or corroded connec-

nections.

tions. Tighten connections.

Defective control switch, starting

Refer to wiring diagrams for cir-

contactor, solenoid switch, or inter-

cuit description and component

lock switch.

location. Replace defective parts.

Battery damage, punctured case, or

Replace battery.

loose terminal posts.

Starter motor brushes worn out.

Repair or replace starter motor.

Starter motor windings defective Replace starter motor.

(shorted or open).

Starter drive assembly damaged.

Replace starter motor.

4-42