CHAPTER 4

STEAM CATAPULTS

Steam catapults are steam powered and direct drive.

In this chapter we describe the basic design of the

steam catapult, while presenting some of the major

differences in the various modifications of the steam

catapult.

When you complete this chapter you should be able

to do the following:

State the functions of the various catapult

systems and their controls.

Describe the operation of the integrated catapult

control station (ICCS) monitor control console.

• Explain the operation and functions of the

C-13/C-13-1 hydraulic charging panel.

• Describe procedures for operating and

monitoring the linear and rotary retraction engines.

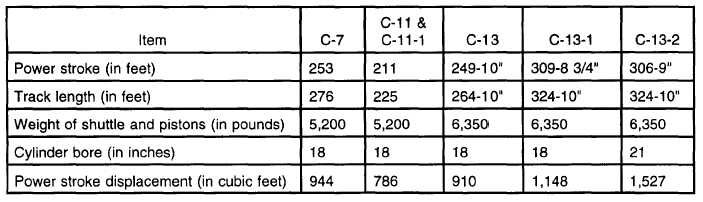

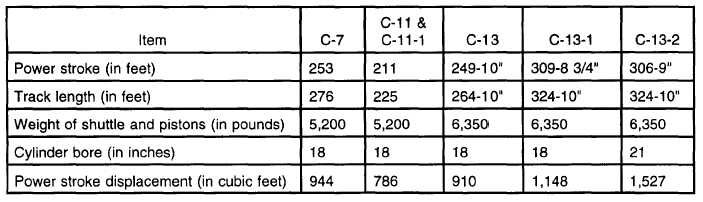

STEAM-POWERED CATAPULTS

Steam is the principal source of energy and is

supplied to the catapults by the ship’s boilers, The

steam is drawn from the ship’s boilers to the catapult

steam receivers or accumulator, where it is stored at the

desired pressure. From the receivers/accumulator, it is

directed to the launching valves, and provides the

energy to launch aircraft. The most significant

differences between the various types of steam catapults

are the length and capacity. See table 4-1 for the

differences.

DESCRIPTION OF OPERATION

A steam fill-valve system controls the amount of

steam from the ship’s boilers to either the dry-steam

receivers or the wet-steam accumulator, depending on

your ship’s catapult steam system. Steam from the

steam receivers/accumulator is then released into the

launching engine cylinders through a set of launch

valves (the amount of steam used is varied by a

capacity selector valve [CSV] assembly that controls the

launch valve opening rate).

This surge of steam acts on a set of steam pistons

inside the launching engine cylinders. These pistons are

connected to a shuttle that is attached to an aircraft (see

fig. 4-1). The force of the steam being released from

the steam receivers/accumulator pushes the pistons

forward, towing the shuttle and aircraft at an increasing

speed until aircraft take-off is accomplished.

The shuttle and steam pistons are stopped at the end

of their “power stroke” as a tapered spear (figs. 4-1 and

4-2) enters a set of water-filled cylinders, forcing the

water to be “metered” out of the cylinders as the

tapered spear moves into them.

After the shuttle and pistons have been stopped, a

grab is advanced forward along the catapult trough

covers by means of the retraction engine, and attaches

to the shuttle assembly. The retraction engine is then

reversed and returns the grab, shuttle, and piston

assembly to the battery position in preparation for the

next aircraft launch.

Table 4-1.—Steam Catapult Data

4-1