NOTE

If during the grit blast operation the gun

becomes clogged, it maybe necessary to sift

foreign matter from the grit. This is

accomplished by using a sieve furnished with

the grit blasting cabinet.

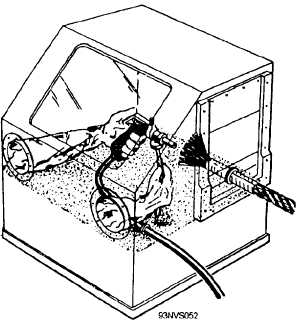

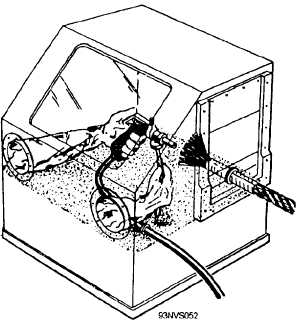

6. Repeat the process until the entire exposed

area of wire rope has been grit blasted. Finally,

direct the nozzle into the open end of the

broomed-out wires at about 30° from the

longitudinal, and rotate the wire rope slowly through

360° while blasting with a circular motion. See

figure 3-52. Remove the wire rope from the cabinet

and inspect it for completeness of grit blasting. Any

evidence of shine will indicate a need for additional

grit blasting.

CAUTION

After being grit blasted, the wires should

not be touched with hands, rags, gloves, and

so on, or the cleanliness required for sound

terminals will be impaired.

7. Shake the wire rope vigorously, broomed-out

end down, to remove any grit between the wires or

in the hemp center.

Figure 3-52.—Blasting inner wires.

CAUTION

Only air from the cabinet supply is used

to remove grit; do NOT use any other

source, because other sources may be

contaminated with oil or water.

8. Remove the grit-siphon tube from the grit

supply, and air blast the wire rope to remove the

remaining grit.

NOTE

After grit blasting a total of 15

broomed-out ends, drain off 10 pounds of

used grit from the bottom of the hopper and

replace it with 10 pounds of new grit.

9. Remove the tape from the wire rope.

10. Prepare a

Fluxing

For solution

solution and flux the wire rope.

preparation and fluxing, the

following procedures are used:

1. Heat the pre-mixed solution until the

temperature is between 160 and 210°F, using the

hotplate provided. Measure the temperature of the

solution with the bimetallic thermometer. Allow the

solution to remain at this temperature for 5

minutes, then remove it from the hotplate and allow

it to cool to room temperature.

2. Remove any scum or foreign matter from

the surface of the cooled solution with clean napkins

or wiping towels.

Do NOT agitate the solution

during this operation.

3. Carefully pour the clear, cooled solution into

another stainless steel container. Avoid pouring any

foreign matter into this container.

NOTE

If the hot-air drying method is used, the

solution can be used cold. If the cable is to

be dried by natural air, use the procedures

listed in step 4.

4. Heat the clear flux solution until the

temperature is between 160 and 210°F.

3-55