The lip or cutting edge of a drill is that part of the

point that actually cuts away the metal when drilling

a hole. It is ordinarily as sharp as the edge of a knife.

There is a cutting edge for each flute of the drill.

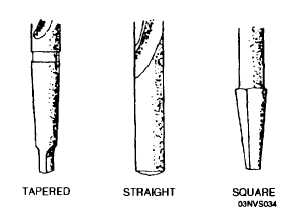

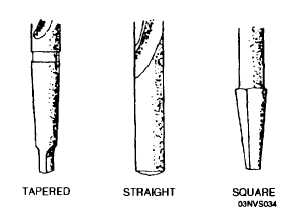

The shank is the part of the drill that fits into the

socket, spindle, or chuck of the drill press. Several

types exist (fig. 1-34).

The maintenance of twist drills and more about

how to use them on specific jobs are discussed later.

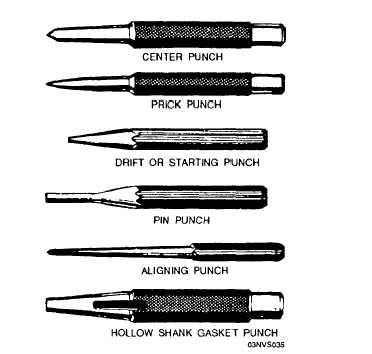

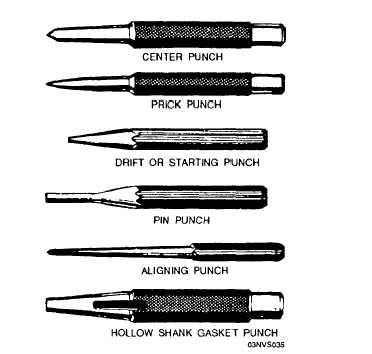

PUNCHES

A hand punch is a tool that is held in the hand

and struck on one end with a hammer. There are

many kinds of punches designed to do a variety of

jobs. Figure 1-35 shows several types of punches.

Most punches are made of tool steel. The part held in

the hand is usually octagonal in shape, or it may be

knurled. This prevents the tool from slipping around

in the hand.

The other end is shaped to do a

particular job.

When you use a punch, there are two things to

remember:

1. When you hit the punch, you do not want it

to slip sideways over your work.

2. You do not want the hammer to slip off the

punch and strike your fingers. You can eliminate both

of these troubles by holding the punch at right angles

to the work and striking the punch squarely with your

hammer.

Figure 1-34.-Representative shanks.

Figure 1-35.-Punches.

The center punch, as the name implies, is used for

marking the center of a hole to be drilled. If you try

to drill a hole without first punching the center, the

drill will “wander” or “walk away” from the desired

center.

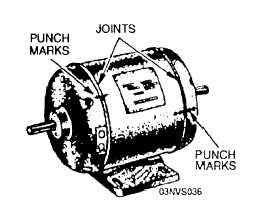

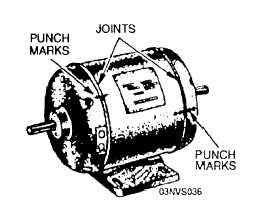

Another use of the center punch is to make

corresponding marks on two pieces of an assembly to

permit reassembling in the original positions. Before

taking a mechanism apart, make a pair of center

punchmarks in one or more places to help in

reassembly. To do this, select places, staggered as

shown in figure 1-36, where matching pieces are

joined. First, clean the places selected. Then, scribe

a line across the joint, and center punch the line on

both sides of the joint, with single and double marks

Figure 1-36.-Punch marking mating parts.

1-22