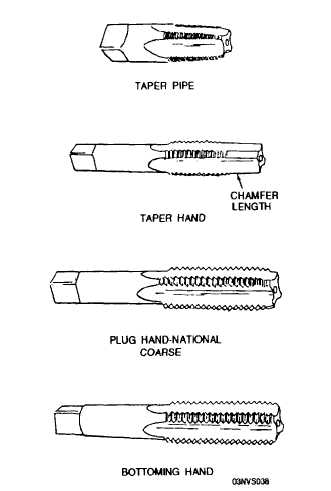

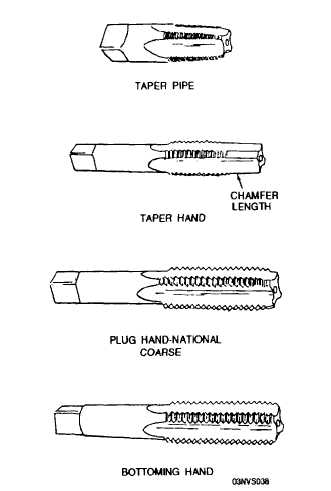

Figure 1-38.-Types of common taps.

Plug hand taps have a chamfer length of 3 to 5

threads and are designed for use after the taper tap.

Bottoming hand taps are used for threading the

bottom of a blind hole. They have a very short

chamfer length of only 1 to 1 1/2 threads for this

purpose. This tap is always used after the plug tap

has been used. Both the taper and plug taps should

precede the use of the bottoming hand tap.

Pipe taps are used for pipe fittings and other

places where extremely tight fits are necessary. The

tap diameter, from end to end of the threaded portion,

increases at the rate of 3/4 inch per foot. All the

threads on this tap do the cutting, as compared to the

straight taps, where only the nonchamfered portion

does the cutting.

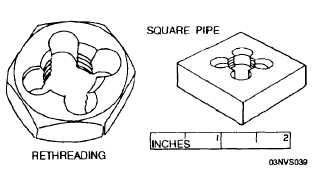

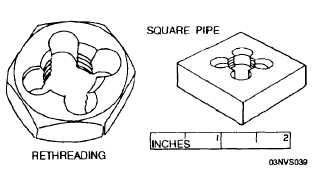

Dies are made in several different shapes and are

of the solid or adjustable type. The square pipe die

(fig. 1-39) will cut American Standard Pipe thread

Figure 1-39.-Types of solid dies.

only. It comes in a variety of sizes for cutting threads

on pipe with diameters of 1/8 inch to 2 inches.

A rethreading die (fig. 1-39) is used principally

for dressing over bruised or rusty threads on screws or

bolts.

It is available in a variety of sizes for

rethreading American Standard Coarse and Fine

threads. These dies are usually hexagon in shape and

can be turned with a socket, box, open-end, or any

wrench that will fit. Rethreading dies are available in

sets of 6, 10, 14, and 28 assorted sizes in a case.

Round split adjustable dies (fig. 1-40) are called

“Burton” dies and can be used in either hand diestocks

or machine holders. The adjustment in the screw

adjusting type is made by a fine-pitch screw, which

forces the sides of the die apart or allows them to

spring together. The adjustment in the open adjusting

type is made by means of three screws in the holder,

one for expanding and two for compressing the dies.

Two piece collet dies (fig. 1-40) are used with a

collet cap (fig. 1-41) and collet guide. The die halves

are placed in the cap slot and are held in place by the

guide, which screws into the underside of the cap.

The die is adjusted by setscrews at both ends of the

interval slot. This type of adjustable die is issued in

various sizes to cover the cutting ranges of American

Standard Coarse and Fine and special-form threads.

Diestocks to hold the dies come in three different

sizes.

Two-piece rectangular pipe dies (fig. 1-40) are

available to cut American Standard Pipe threads.

They are held in ordinary or ratchet-type diestocks

(fig. 1-42).

Threading sets are available in many different

combinations of taps and dies, together with diestocks,

tap wrenches, guides, and necessary screwdrivers and

1-24