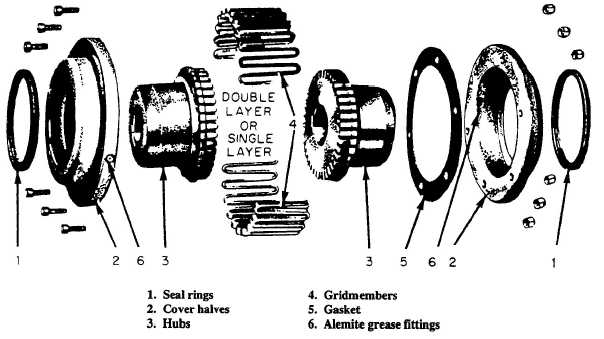

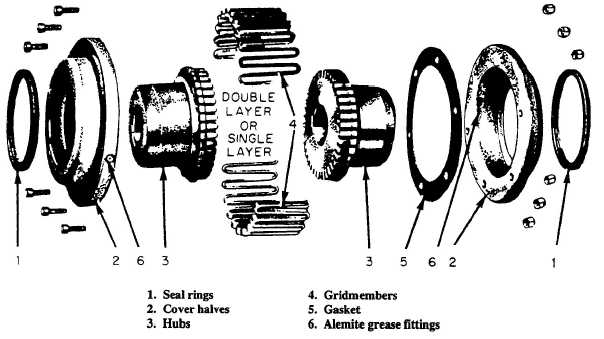

Figure 4-12.—Falk Type-F Steelflex coupling.

coupling is normally gained from a gear, a spring

arrangement, or a rubber insert between the coupling

halves. Depending on the type of coupling, lubrication

may or may not be required.

Falk Type-F Steelflex Coupling

This coupling (fig. 4-12) is a flexible, self-

aligning, gridmember coupling. The two hubs are

symmetrical, but may have different bores or

keyways. One hub is keyed to the motor shaft, and

the other hub is keyed to the pump shaft and secured

axially by set screws. A flexible gridmember engages

the teeth in the hubs to transmit power. A gasket and

two seal rings are fitted to the covers to prevent

grease leakage. The parts are enclosed in two cover

halves that are bolted together.

When it is necessary to disconnect the coupling,

remove the nuts and bolts, separate and draw back

the cover halves, and remove the gridmember. To

remove the gridmember, a round rod or screwdriver

that conveniently fits into the open loop ends of the

gridmember is required. Begin at the open end of the

gridmember section and insert the rod or screwdriver

into the loop ends. Use the teeth next to each loop as

a fulcrum and pry the gridmember out radially in

even, gradual stages. Proceed alternately from side to

side lifting the gridmember about halfway out until

the end of the gridmember is reached. Using the

same procedure again, lift the gridmember until the

teeth are cleared. This separates the coupling hubs.

Before reassembly, clean all parts thoroughly

and check the coupling alignment in accordance with

the pump’s technical manual.

After the coupling is aligned, carefully insert the

gasket between the hubs and hang it on either hub.

Do not damage the gasket. Next, force as much

lubricant as possible into the space between the hubs

and grid-member grooves.

Insert the gridmembers. To accomplish this with

a minimum amount of spreading, start the

gridmember at either end and tap the rungs only part

way into the grooves. After all the rungs are partially

in their respective grooves, tap the gridmember all

the way into place. The hub grooves on each hub are

uniformly spaced and do not require matching. Again

pack lubricant in the spaces between and around the

gridmember, then wipe off the excess flush with the

top of the gridmember. Lightly oil the hubs to ease

the sliding of the covers onto the hubs. Mount the

covers so the lubrication fittings are 180 degrees

apart. Insert a screwdriver under the seal ring for

venting purposes and then tighten the cover bolts.

Remove the screw-driver, check the seal rings for

proper seating, and align the cover to prevent wobble.

4-17