prongs down into the four flutes of the tap. Then slide

the bottom collar down to the surface of the work so

it will hold the prongs tightly against the body of the

extractor. Tighten the tap wrench on the square shank

of the extractor and carefully work the extractor back

and forth to loosen the tap. It may be necessary to

remove the extractor and strike a few sharp blows

with a small hammer and pin punch to jar the tap

loose. Then reinsert the tap remover and carefully try

to back the tap out of the hole.

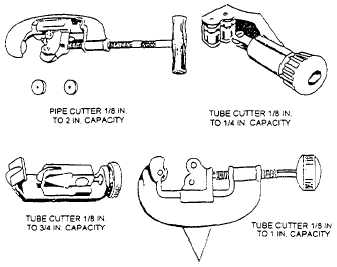

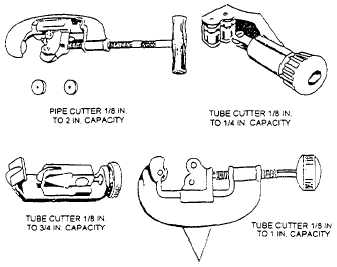

Figure 2-16.—Pipe and tubing cutters.

PIPE AND TUBING CUTTERS

AND FLARING TOOLS

Pipe cutters (fig. 2-16) are used to cut pipe made

of steel, brass, copper, wrought iron, and lead. Tube

cutters (fig. 2-16) are used to cut tubing made of iron,

steel, brass, copper, and aluminum. The essential dif-

ference between pipe and tubing is that tubing has

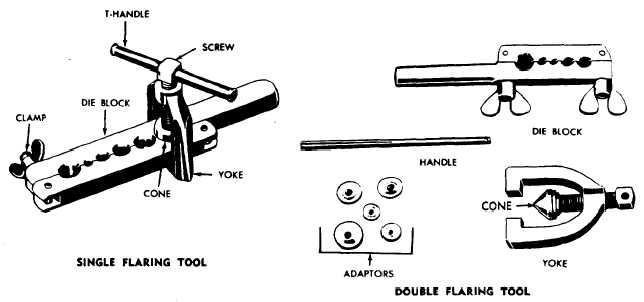

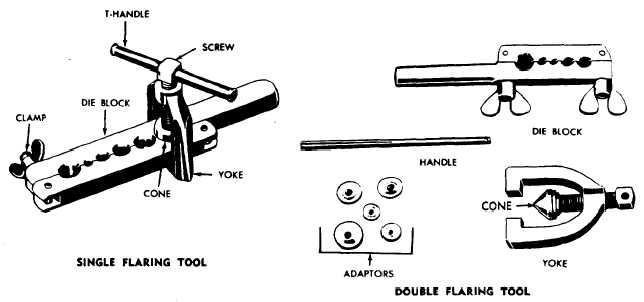

considerably thinner walls. Flaring tools (fig. 2-17)

are used to make single or double flares in the ends of

tubing.

Two sizes of hand pipe cutters are generally used

in the Navy. The No. 1 pipe cutter has a cutting

capacity of 1/8 to 2 inches, and the No. 2 pipe cutter

has a cutting capacity of 2 to 4 inches. The pipe cutter

has a special alloy-steel cutting wheel and two pres-

sure rollers that are adjusted and tightened by turning

the handle.

Most tube cutters closely resemble pipe cutters,

except they are of lighter construction. A hand screw

feed tubing cutter of 1/8-inch to 1 1/4-inch capacity

has two rollers with cutouts located off center so that

cracked flares may be held in them and cut off without

waste of tubing. It also has a retractable cutter blade

that is adjusted by turning a knob. The other tube

cutter shown is designed to cut tubing up to and

including 3/4- and 1-inch O.D. Rotation of the trian-

gular portion of the tube cutter within the tubing will

eliminate any burrs.

Flaring tools are used to flare soft copper, brass,

or aluminum. The single flaring tool consists of a split

Figure 2-17.—Flaring tools.

2-11