There are five basic ways manufacturers

can correct this front-end, low-speed, high-

temperature stall:

1. Lowering the angle of attack on the front

stages so the high angles at low engine speed are

not stall angles

2. Installing a bleed valve in the middle or rear

of the compressor to bleed air and increase airflow

in the front of the compressor at low engine speeds

3. Splitting the compressor into two rotors

and designing the front rotor rpm to decrease

more than the rear rotor at low speeds, so low

front-rotor speed will equal the low choked

airflow

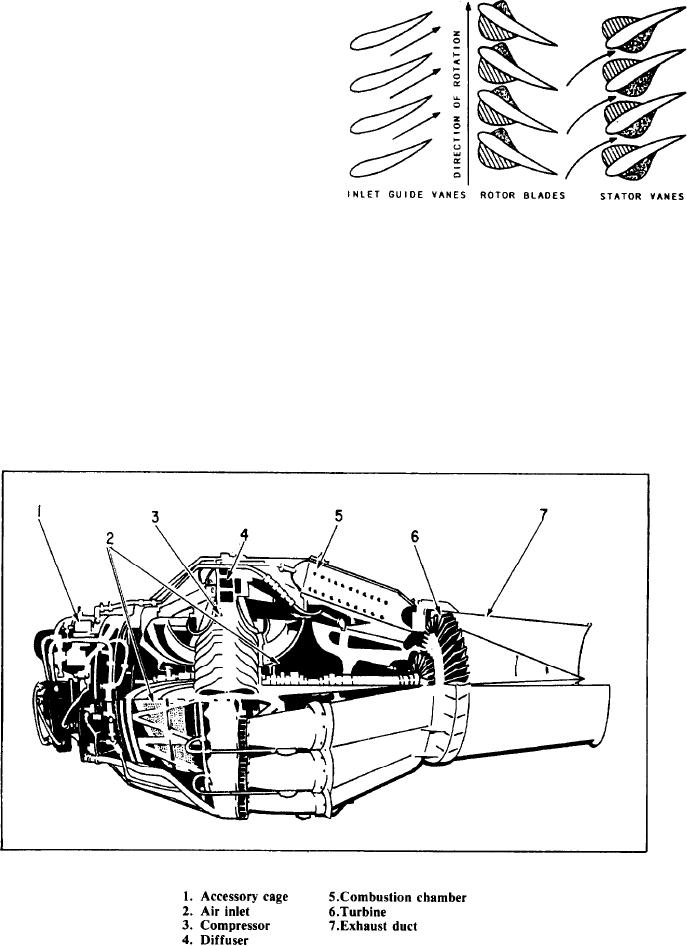

Figure 1-18.-The cascade effect.

4. Installing variable inlet-guide vanes and

variable stators in the front of the first series of

compressor stages so the angle of attack is

The stator has rows of blades or vanes

changed at low engine speed

dovetailed into split rings and attached inside an

5. Using a variable-area exhaust nozzle to

enclosing case. The stator vanes project radially

unload the compressor during acceleration

toward the rotor axis and fit closely on either side

of each stage of the rotor.

NOTE: A combination of any of the above

The compressor case, into which the stator

may be used.

vanes fit, is horizontally divided into halves.

Figure 1-17.-Centrifugal-flow engine (J33).

1-15