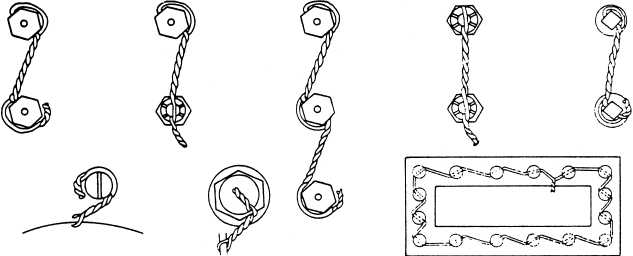

Step 1. Assemble the unit. Torque the bolts and

carefully align the safety wire holes.

Step 2. Insert the proper size wire through the

hole in the first bolt.

Step 3. Bend the left end of the wire clockwise

around the bolt head and under the other end of the

wire.

Step 4. Pull the loop tight against the bolt head.

Grasp both ends of the wire. Twist them in a clockwise

direction until the end of the braid is just short of the

second bolt.

Step 5. Check to ensure that the loop is still

tightly in place around the first bolt head. Grasp the

wire with pliers just beyond the end of the braid. While

holding it taut, twist it in a clockwise direction until the

braid is stiff.

NOTE:

The braid must be tight enough to resist

friction

or

vibration

wear,

but

should

not

be

overtightened.

Step 6. Insert the upper end of the safety wire

through the hole in the second bolt. Pull the braid until

it is taut.

Step 7. Bring the other end of the wire counter-

clockwise around the bolt head and

under

the

protruding wire end.

Step 8. Tighten the loop and braid the wire ends in

a counterclockwise direction. Grasp the wire with the

pliers just beyond the end of the braid and twist in a

counterclockwise direction until the braid is stiff. Make

sure you keep the wire under tension.

Step 9.

With a final twisting motion, bend the

braid to the right and against the head of the bolt.

Step 10. Cut the braid, being careful that between

three and six full twists still remain. Avoid sharp

projecting ends.

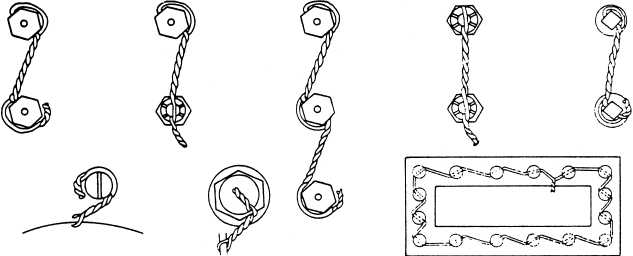

Figure 5-23 shows various methods commonly

used in safety wiring nuts, bolts, and screws. Examples

1, 2, and 5 of figure 5-23 show the proper method of

safety wiring bolts, screws, square head plugs, and

similar parts when wired in pairs. Examples 6 and 7

show a single-threaded component wired to a housing

or lug. Example 3 shows several components wired in

series. Example 4 shows the proper method of wiring

castellated nuts and studs. Note that there is no loop

around the nut. Example 8 shows several components

in a closely spaced, closed geometrical pattern, using

the single-wire method.

When drilled-head bolts, screws, or other parts are

grouped together, they are more conveniently safety

wired to each other in a series rather than individually.

The number of nuts, bolts, or screws that may be safety

wired together depends on the application. For

instance, when you are safety wiring widely spaced

bolts by the double-twist method, a group of three

should be the maximum number in a series.

When you are safety wiring closely spaced bolts,

the number that can be safety wired by a 24-inch length

of wire is the maximum in a series. The wire is arranged

in such a manner that if the bolt or screw begins to

loosen, the force applied to the wire is in the tightening

direction.

5-16

ANF0523

1

2

3

4

5

6

7

8

Figure 5-23.—Safety wiring methods.