When you perform an inspection, both bonding

connections and safetying devices must be inspected

with great care.

Q5-10.

What manual should you consult to find

correct

replacement

wires

for

a

given

aircraft?

SAFETY METHODS

LEARNING OBJECTIVE:

Recognize the

procedures for the safetying of fasteners and

electrical system hardware.

Safetying is a process of securing all aircraft bolts,

nuts, capscrews, studs, and other fasteners. Safetying

prevents the fasteners from working loose due to

vibration. Loose bolts, nuts, or screws can ruin engines

or cause parts of the aircraft to drop off. To carry out an

inspection on an aircraft, you must be familiar with the

various methods of safetying. Careless safetying is a

sure road to disaster. Always use the proper method for

safetying. Always safety a part you have just unsafetied

before going on to the next item of inspection. You

should always inspect for proper safetying throughout

the area in which you are working.

There are various methods of safetying aircraft

parts. The most widely used methods are safety wire,

cotter pins, lock washers, snap rings, and special nuts.

Some of these nuts and washers have been described

previously in this chapter.

SAFETY WIRING

Safety wiring is the most positive and satisfactory

method of safetying. It is a method of wiring together

two or more units. Any tendency of one unit to loosen is

counteracted by the tightening of the wire.

Nuts, Bolts, and Screws

Nuts, bolts, and screws are safety wired by the

single-wire double-twist method. This method is the

most common method of safety wiring. A single-wire

may be used on small screws in close spaces, closed

electrical systems, and in places difficult to reach.

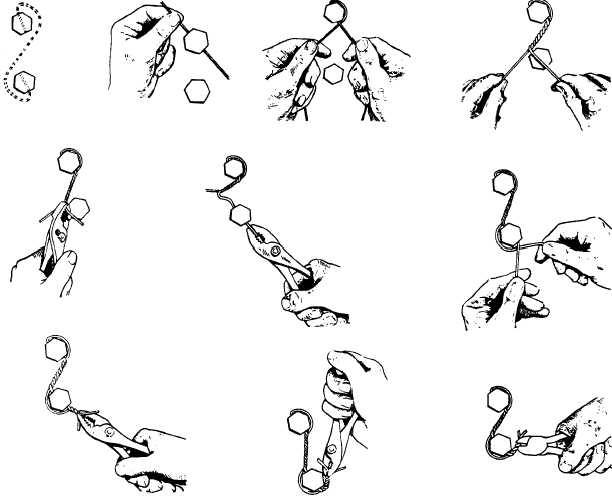

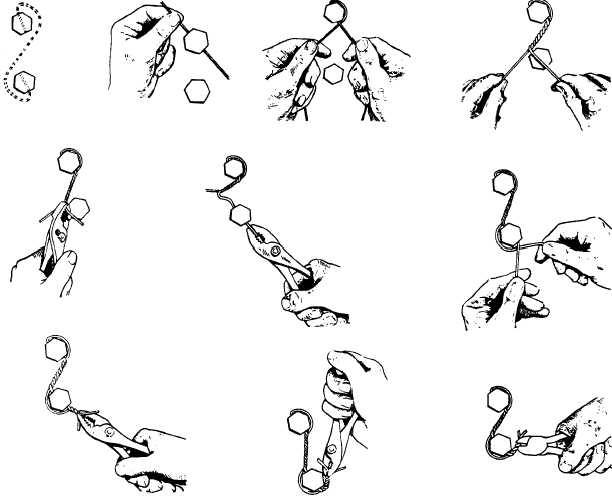

Figure 5-22 illustrates the following steps required

to install a standard double-twist safety wire for two

bolts with right-hand threads.

5-15

ANF0522

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

STEP 7

STEP 8

STEP 9

STEP 10

Figure 5-22.—Standard double-twist safety wire installation procedures.