The elastic stop nut is constructed with a

nonmetallic (nylon) insert, which is designed to lock

the nut in place. The insert is unthreaded and has a

smaller diameter than the inside diameter of the nut.

Self-locking nuts are generally suitable for reuse in

noncritical applications provided the threads have not

been damaged. If the locking material has not been

damaged or permanently distorted, it can be reused.

NOTE: If any doubt exists about the condition of a

nut, use a new one!

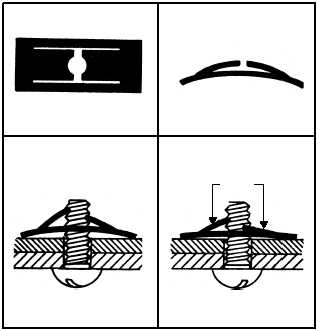

When you anchor lightweight parts, the sheet

spring nut may be used. See figure 5-8. Applications

include supporting line clamps, electrical equipment,

and small access doors. It is made of sheet spring steel

and is cut so as to have two flaps. The ends of these

flaps are notched to form a hole that is somewhat

smaller in diameter than the screw used. The sheet

spring nut has a definite arch that tends to flatten out as

the screw pulls the flaps in toward the threads. This

flattening action forces the flaps of the nut tightly into

the threads of the screw. The springiness of the sheet

spring nut pushes upward on the screw threads, binding

them and locking the screw in place. With the sheet

spring nut, either a standard or a sheet metal

self-tapping screw is used.

INSTALLATION OF NUTS AND BOLTS

You must be certain that each bolt is made of the

correct material. Examine the markings on the head to

determine whether a bolt is steel or aluminum alloy.

It is of extreme importance to use like bolts in

replacement. In every case, refer to the applicable

maintenance instruction manual and illustrated parts

breakdown.

Be sure that washers are used under the heads of

both bolts and nuts unless their omission is specified. A

washer guards against mechanical damage to the

material being bolted and prevents corrosion of the

structural members. An aluminum alloy washer may be

used under the head and nut of a steel bolt securing

aluminum

alloy

or

magnesium

alloy

members.

Corrosion will attack the washer rather than the

members. Steel washers should be used when joining

steel members with steel bolts.

Whenever possible, the bolt should be placed with

the head on top or in the forward position. This

positioning helps prevent the bolt from slipping out if

the nut is accidentally lost.

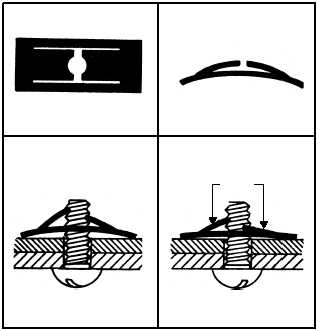

Make sure that the bolt grip length is correct.

Generally speaking, the grip length should equal the

thickness of the material being bolted together. Not

more than one thread should bear on the material, and

the shank should not protrude too far through the nut.

Figure 5-2 shows examples of correct and incorrect grip

length.

Application of Torque

Torque is the amount of twisting force applied

when you are tightening a nut. If torque values are

specified in the appropriate manual, a torque wrench

must be used. Regardless of whether torque values are

specified or not, all nuts in a particular installation must

be tightened a like amount. This permits each bolt in a

group to carry its share of the load. It is a good practice

to use a torque wrench in all applications.

Safetying of Nuts and Bolts

It is very important that all nuts except the

self-locking type be safetied after installation. This

prevents nuts from loosening in flight because of

vibration. Methods of safetying are discussed later in

this chapter.

Q5-2.

What are the three principal parts of a bolt?

Q5-3.

What are the three most commonly used

screws in aircraft construction?

Q5-4.

What general group of aircraft nuts require

an external locking device, such as cotter

pins, safety wire, or locknuts?

5-6

ANF0508

TOP VIEW

SIDE VIEW

STARTING POSITION

DOUBLE-LOCKED

POSITION

INWARD

THREAD

LOCK

A

B

C

D

Figure 5-8.—Sheet spring nut.