METALLIC MATERIALS

The most common metals used in aircraft

construction are aluminum, magnesium, titanium,

steel, and their alloys.

Aluminum

Aluminum alloys are widely used in modern

aircraft construction. Aluminum alloys are valuable

because they have a high strength-to-weight ratio.

Aluminum

alloys

are

corrosion

resistant

and

comparatively easy to fabricate. The outstanding

characteristic of aluminum is its lightweight.

Magnesium

Magnesium is the world's lightest structural metal.

It is a silvery-white material that weighs two-thirds as

much as aluminum. Magnesium is used to make

helicopters. Magnesium's low resistance to corrosion

has limited its use in conventional aircraft.

Titanium

Titanium is a lightweight, strong, corrosion-

resistant metal. Recent developments make titanium

ideal for applications where aluminum alloys are too

weak and stainless steel is too heavy. Additionally,

titanium is unaffected by long exposure to seawater and

marine atmosphere.

Alloys

An alloy is composed of two or more metals. The

metal present in the alloy in the largest amount is called

the base metal. All other metals added to the base metal

are called

alloying elements. Adding the alloying

elements may result in a change in the properties of the

base metal. For example, pure aluminum is relatively

soft and weak. However, adding small amounts or

copper, manganese, and magnesium will increase

aluminum's strength many times. Heat treatment can

increase or decrease an alloy's strength and hardness.

Alloys are important to the aircraft industry. They

provide materials with properties that pure metals do

not possess.

Steel Alloys

Alloy steels used in aircraft construction have great

strength, more so than other fields of engineering would

require. These materials must withstand the forces that

occur on today's modern aircraft. These steels contain

small percentages of carbon, nickel, chromium,

vanadium, and molybdenum. High-tensile steels will

stand stress of 50 to 150 tons per square inch without

failing. Such steels are made into tubes, rods, and wires.

Another type of steel used extensively is stainless

steel. Stainless steel resists corrosion and is particularly

valuable for use in or near water.

NONMETALLIC MATERIALS

In addition to metals, various types of plastic

materials are found in aircraft construction. Some of

these plastics include transparent plastic, reinforced

plastic, composite, and carbon-fiber materials.

Transparent Plastic

Transparent

plastic

is

used

in

canopies,

windshields, and other transparent enclosures. You

need to handle transparent plastic surfaces carefully

because they are relatively soft and scratch easily. At

approximately 225°F, transparent plastic becomes soft

and pliable.

Reinforced Plastic

Reinforced plastic is used in the construction of

radomes, wingtips, stabilizer tips, antenna covers, and

flight

controls.

Reinforced

plastic

has

a

high

strength-to-weight ratio and is resistant to mildew and

rot. Because it is easy to fabricate, it is equally suitable

for other parts of the aircraft.

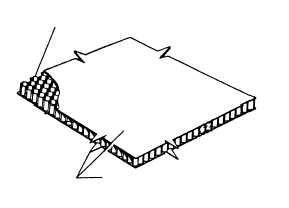

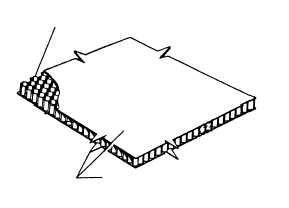

Reinforced plastic is a sandwich-type material (fig.

4-4). It is made up of two outer facings and a center

layer. The facings are made up of several layers of glass

cloth, bonded together with a liquid resin. The core

material (center layer) consists of a honeycomb

4-4

HONEYCOMB

CORE

FACINGS

(MULTIPLE LAYERS OF GLASS CLOTH)

Anf0404

Figure 4-4.—Reinforced plastic.