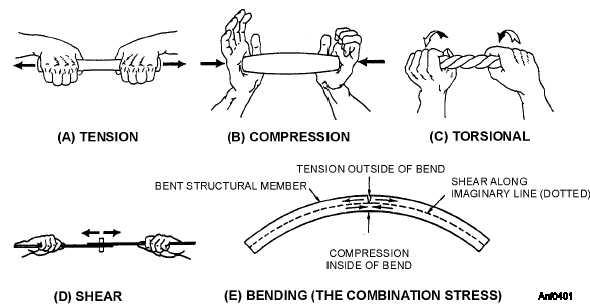

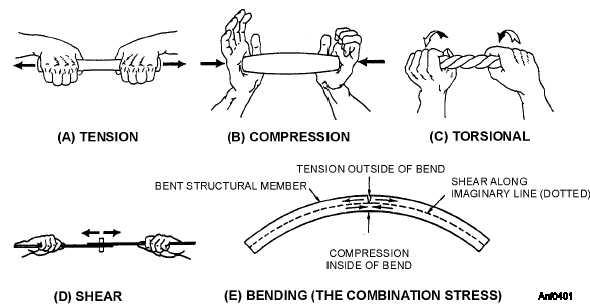

SHEAR

Cutting a piece of paper with scissors is an example

of a shearing action. In an aircraft structure, shear (fig.

4-1, view D) is a stress exerted when two pieces of

fastened material tend to separate. Shear stress is the

outcome of sliding one part over the other in opposite

directions. The rivets and bolts of an aircraft experience

both shear and tension stresses.

BENDING

Bending (fig. 4-1, view E) is a combination of

tension and compression. For example, when bending a

piece of tubing, the upper portion stretches (tension)

and the lower portion crushes together (compression).

The wing spars of an aircraft in flight are subject to

bending stresses.

TORSION

Torsional (fig. 4-1, view C) stresses result from a

twisting force. When you wring out a chamois skin, you

are putting it under torsion. Torsion is produced in an

engine crankshaft while the engine is running. Forces

that produce torsional stress also produce torque.

VARYING STRESS

All structural members of an aircraft are subject to

one or more stresses. Sometimes a structural member

has alternate stresses; for example, it is under

compression one instant and under tension the next.

The strength of aircraft materials must be great enough

to withstand maximum force of varying stresses.

SPECIFIC ACTION OF STRESSES

You need to understand the stresses encountered on

the main parts of an aircraft. A knowledge of the basic

stresses on aircraft structures will help you understand

why aircraft are built the way they are. The fuselage of

an aircraft is subject the fives types of stress—torsion,

bending, tension, shear, and compression.

Torsional stress in a fuselage is created in several

ways. For example, torsional stress is encountered in

engine torque on turboprop aircraft. Engine torque

tends to rotate the aircraft in the direction opposite to

the direction the propeller is turning. This force creates

a torsional stress in the fuselage. Figure 4-2 shows the

effect of the rotating propellers. Also, torsional stress

on the fuselage is created by the action of the ailerons

when the aircraft is maneuvered.

When an aircraft is on the ground, there is a

bending force on the fuselage. This force occurs

because of the weight of the aircraft. Bending increases

when the aircraft makes a carrier landing. This bending

action creates a tension stress on the lower skin of the

fuselage and a compression stress on the top skin.

Bending action is shown in figure 4-3. These stresses

are transmitted to the fuselage when the aircraft is in

flight. Bending occurs because of the reaction of the

airflow against the wings and empennage. When the

4-2

Figure 4-1.—Five stresses acting on an aircraft.