POWER

SECTION.—The

power

section

consists of an axial-flow compressor, a combustion

chamber, a multi-stage turbine, and an exhaust section.

The last two stages of the turbine are used to drive the

propeller using the torquemeter assembly and the

reduction gear assembly.

TORQUEMETER ASSEMBLY.—The torque-

meter assembly electronically measures the torsional

deflection (twist). Torsional deflection occurs in the

power transmitting shaft that connects the power

section to the reduction gear assembly. This torsional

deflection is recorded as horsepower.

REDUCTION

GEAR

ASSEMBLY.—The

reduction gear assembly reduces the engine rpm within

the range of efficient propeller rpm. The ratio on some

installations is as high as 12 or 13 to 1. This large

reduction ratio is necessary because the gas turbine

must operate at a very high rpm to produce power

efficiently. This engine operates at a constant rpm. The

propeller blade angle changes for an increase or

decrease in power while the engine rpm remains the

same.

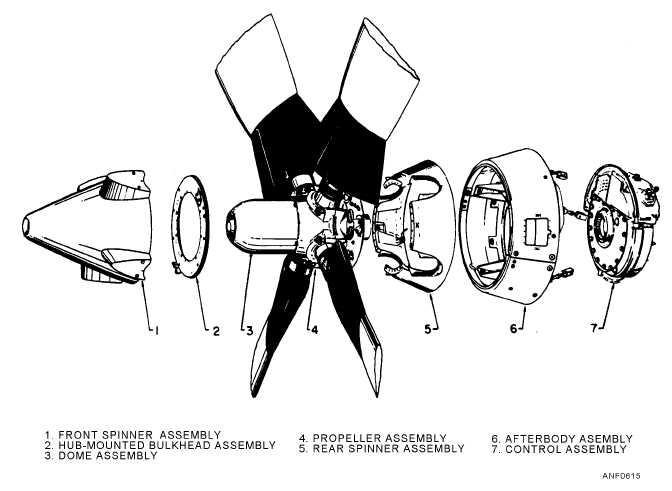

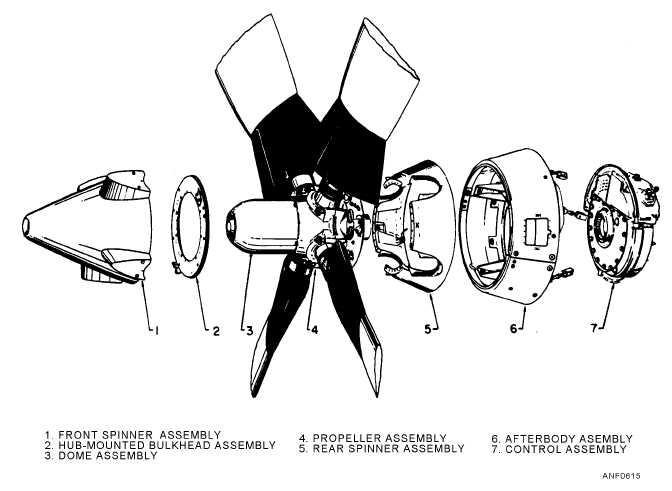

The typical propeller assembly for a turboprop

engine (fig. 6-15) consists of a front and rear spinner

assembly, a hub-mounted bulkhead assembly, the dome

assembly, four blades, an afterbody fairing assembly,

and a propeller control assembly. The propeller

assembly converts the power developed by the engine

into thrust as efficiently as possible under all operating

conditions.

Turboshaft Engines

There are many different models of this type of

engine. The H-46 and H-53 helicopters are examples of

aircraft that use this engine.

6-9

Figure 6-15.—Propeller assembly and associated parts.