COMBUSTION CHAMBER.—The efficiency

and performance of a turbine power unit depend on the

type

of

combustion

system

used.

The

basic

requirements for a satisfactory system are a high rate of

burning, minimum pressure drop, small bulk, and light

weight. The system must be consistent in operation

over a wide range of loads and altitudes, with no

tendency to flood with fuel or suffer

combustion

blowout. Combustion blowout is a flame failure, and it

is primarily a problem in high-altitude operation.

Starting must be easy and positive, both on the ground

and in the air. Combustion must be complete to avoid

formation of carbon deposits.

Fuel enters the front of the burner as an atomized

spray or in a prevaporized form. Air flows in around the

fuel nozzle and through the first row of combustion air

holes in the liner. Air near the burner nozzle stays close

to the front liner wall for cooling and cleaning

purposes. Air entering through opposing liner holes

mixes rapidly with the fuel to form a combustible

mixture. Air entering the forward section of the liner

recirculates and moves upstream against the fuel spray.

During combustion, this action permits rapid mixing

and prevents flame blowout by forming a low-velocity

stabilization zone. This zone acts as a continuous pilot

for the rest of the burner. Air entering the downstream

part of the liner provides the correct mixture for

combustion. This air also creates the intense turbulence

necessary for mixing the fuel and air and for

transferring energy from the burned to the unburned

gases.

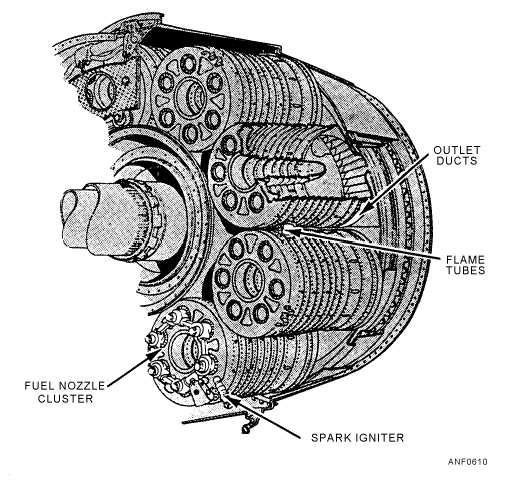

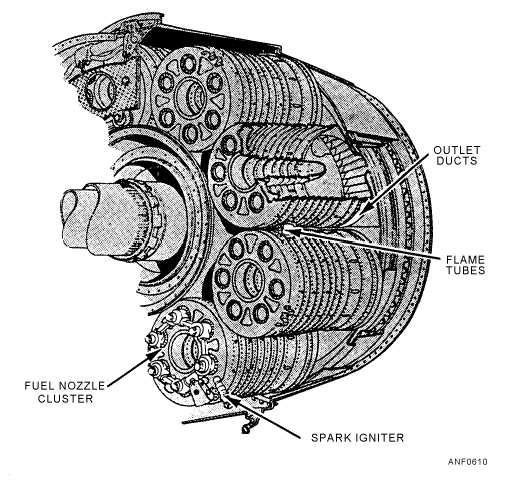

Since an engine usually has two igniter plugs, cross

ignition tubes are necessary in the can and can-annular

types of burners. These tubes allow burning to start in

the other cans or inner liners. Axial-flow engines use

either an annular or the can-annular (fig. 6-10) type of

combustion chamber. The igniter plug is usually

located in the upstream reverse flow region of the

burner. After ignition, the flame quickly spreads to the

primary (combustion) zone. This zone contains the

correct proportion of air to completely burn the fuel. If

all the air flowing through the engine were mixed with

the fuel at this point, the mixture would be outside the

combustion

limits

for

the

fuel

normally

used.

Therefore, only about one-third to one-half of the air is

allowed to enter the combustion zone of the burner.

About 25 percent of the air actually takes part in the

combustion process.

6-6

Figure 6-10.—Can-annular combustion chamber components and arrangements.