to the propellant ends. The outer surface inhibitor is

spirally wrapped ethyl cellulose tape bonded to the

propellant surface.

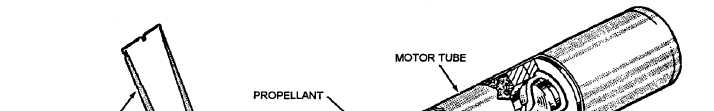

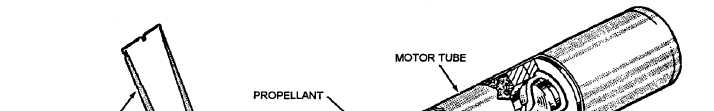

Figure 2-2.—Components of a typical rocket motor.

Inhibitors cause the propellant grain to burn from

the center outward and from forward to aft uniformly.

If inhibitors weren’t used, the burning surface of the

propellant grain would increase, and result in an

increased burning rate. This could cause the motor tube

to explode from excessive pressure. If a motor is

accidentally dropped and the propellant grain is cracked,

the crack in the grain increases the burning surface and

an identical hazard exists.

STABILIZING ROD.— The stabilizing rod (fig.

2-2), located in the perforation of the motor propellant

grain, is salt coated to prevent unstable burning of the

propellant. It also reduces flash and afterburning in the

rocket motor, which could contribute to compressor stall

and flameout of the aircraft jet engines. When the

propellant ignites, the stabilizing rod ensures that the

grain ignites simultaneously forward and aft.

IGNITER.— The igniter (fig. 2-2) heats the

propellant grain to ignition temperature. The igniter

used in the 2.75-inch motor is a disc-shaped

metal container that contains a black powder and

magnesium charge, a squib, and electrical lead wires.

It is located at the forward end of the motor. The

igniter used in the 5.0-inch motor is a disc-shaped

metal container that contains a powder or pellet

charge, two squibs, and electrical lead wires. It is

located at the forward end of the motor. A contact disc

or a contact band transmits the firing impulses to the

motor igniter.

The 2.75-inch motor has electrical leads that extend

from the squib through the wall of the igniter. They are

routed through the propellant perforation to the nozzle

fin assembly. One of the wires is connected to the

nozzle plate (ground), and the other passes through

2-3