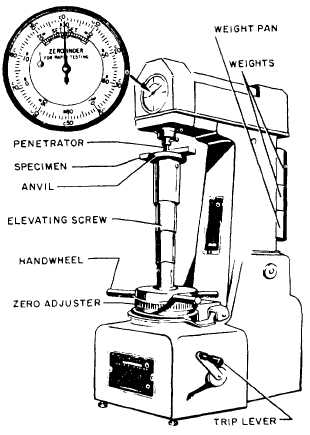

Figure 1-25.—Brinell hardness tester.

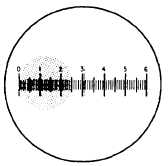

Figure 1-26.—Microscopic view of impression.

BRINELL TESTER

The Brinell hardness tester, shown in figure 1-25,

uses a hardened spherical ball, which is forced into the

surface of the metal. The ball is 10 millimeters (0.3937

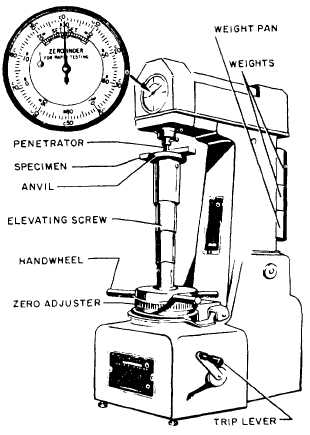

Figure 1-27.—Rockwell hardness tester.

inch) in diameter. A pressure of 3,000 kilograms (6,600

pounds) is used for ferrous metals and 500 kilograms for

nonferrous metals. Normally, the load should be applied

for 30 seconds. In order to produce equilibrium, this

period may be increased to 1 minute for extremely hard

steels. The load is applied by means of hydraulic

pressure. The hydraulic pressure is built up by a hand

pump or an electric motor, depending on the model of

tester. A pressure gauge indicates the amount of

pressure. There is a release mechanism for relieving the

pressure after the test has been made, and a calibrated

microscope is provided for measuring the diameter of

the impression in millimeters. The machine has various

shaped anvils for supporting the specimen and an

elevating screw for bringing the specimen in contact

with the ball penetrator. There are attachments for

special tests.

To determine the Brinell hardness number for a

metal, the diameter of the impression is first measured,

using the calibrated microscope furnished with the

tester. Figure 1-26 shows an impression as seen through

1-36