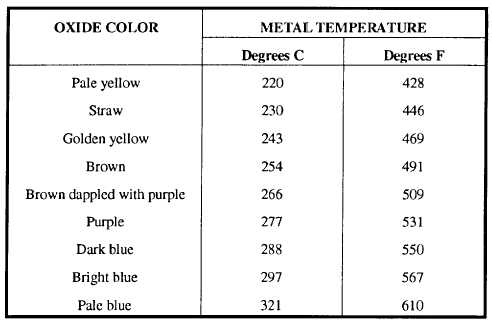

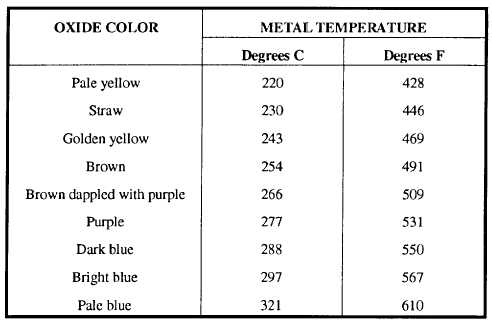

Table 15-2.—Color Chart for Various Tempering Temperatures of Carbon Steel

film of oxide, which forms on the metal after the

Steel is usually subjected to the annealing process

temperature reaches 220°C (428°F). To see the

tempering colors, you must brighten the surface. When

tempering by the color method, an open flame or heated

iron plate is ordinarily used as the heating medium.

Although the color method is convenient, it should not

be used unless adequate facilities for determining

temperatures are not obtainable. The temperatures and

corresponding oxide colors are given in table 15-2.

ANNEALING AND NORMALIZING.—When

steel is heated to a point above its critical range, a

condition referred to as “austenite” is produced. If

slowly cooled from above its critical temperature, the

austenite is broken down and a succession of other

conditions are produced, each being normal for a

particular range of temperatures. Starting with austenite,

these successive conditions are martensite, troostite,

sorbite, and finally pearlite.

The most important step in annealing is to raise the

temperature of the metal to the critical point, as any

hardness that may have existed will then be completely

removed. Strains that may have been set up through heat

treatment will be eliminated when the steel is heated to

the critical point, and then restored to its lowest hardness

by slow cooling. In annealing, the steel must never be

heated more than approximately 28° to 40°C (50° to

75°F) above the critical point. When large articles are

annealed, sufficient time must be allowed for the heat to

penetrate the metal.

for the following purposes:

1. To increase its ductility by reducing hardness

and brittleness.

2. To refine the crystalline structure and remove

residual stresses. Steel that has been cold worked is

usually annealed to increase its ductility.

Assuming that the part to be annealed is heated to

the proper temperature, the required slow cooling may

be accomplished in several ways, depending on the

metal and the degree of softness required.

Normalizing, although involving a slightly

different heat treatment, may be classed as a form of

annealing. This process removes all strains due to

machining, forging, bending, and welding. Normalizing

can only be accomplished with a good furnace, where

the temperatures and the atmosphere may be closely

regulated and held constant throughout the entire

operation. A reducing atmosphere will normalize the

metal with a minimum amount of oxide scale, while an

oxidizing atmosphere will leave the metal heavily

coated with scale, thus preventing proper development

of hardness in any subsequent hardening operation. The

articles are put in the furnace and heated to a point above

the critical temperature of the steel. After the parts have

been held at this temperature for a sufficient time to

allow the heat to penetrate to the center of the section,

they must be removed from the furnace and cooled in

15-42