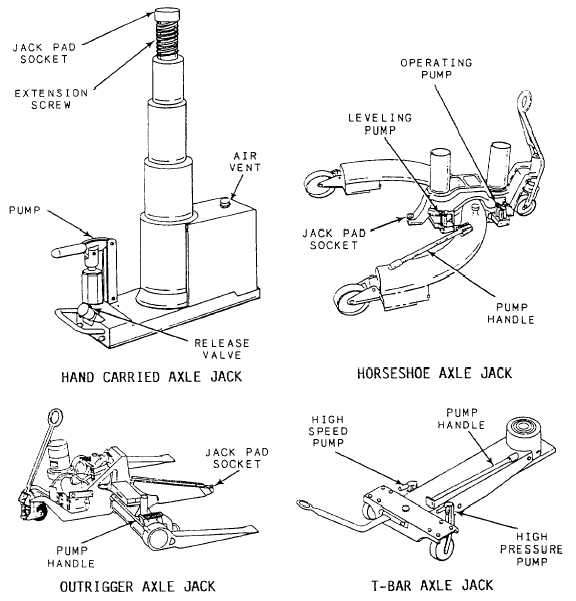

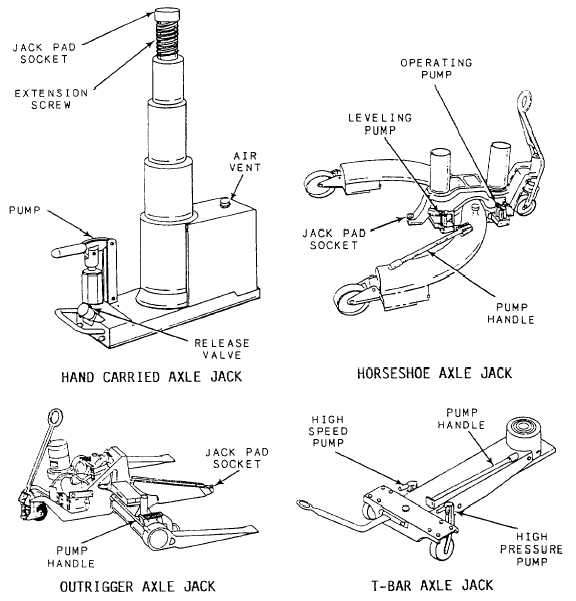

Figure 3-27.—Types of axle jacks.

wheels, and struts. There are four different types of axle

jacks and many different sizes (lifting capacity in tons).

Figure 3-27 shows the four types of Navy axle jacks.

The smaller hydraulic axle jacks are normally squadron

or unit permanent custody equipment. That means your

outfit is responsible for making sure the jacks are load

tested at the support equipment (SE) division of the

aircraft intermediate maintenance department (AIMD)

before being put into service, and annuall y thereafter.

Special inspections include 13 week inspections at

AIMD S/E, but a load test is not required every 13

weeks. A record of maintenance, inspections, technical

directives, and load testing is kept on OPNAV form

4790/51

All model designations for axle jacks begin with the

letter A, for axle, such as A 10-1HC. The number

following the A shows the jack capacit y in tons, such as

10 for a 10-ton jack. This is followed by a dash (-) and

the specific jack identification number. Then comes two

letters that show the type of jack (HC = hand carried,

HS = horseshoe, TB = T-bar, and OR = outrigger).

HAND CARRIED.—These axle jacks are portable,

self-contained units, with single or double manually

operated pumps. They have carrying handles, pump

handles, reservoir vent valves, release valves, and safety

valves. The different model sizes vary from 4 3/4 inches

to 9 inches high (closed). Their weights vary from 26 to

120 pounds.

3-38