AEROL

INFLATION

.INSTRUCTION

nLc*RoILss OrAlnCR*r?

rclw?

YCD.

BY

*Ho

STRUT

fRIC?

IOU, II

STRUT

THE CLEVELAND

PNEUMATIC

TOOLCO.

DIYCMSIOW

.X-

18 YCAWRCD

AWO

DIVISION

Dr

CIC~CLAND

?wCuwr?~C

?acssunC

OIVCM

IN TWL TABLL

to

l*DUS?RlCS

NC,

CLCVCLAwD,O)crO,U.SA

WC

LCFT,

DOES

NOT CDRICSPDMD

IOR

CRU~MAW

AlRCRA,lT

~NCI~CCIIWG

CORP.

TO THAT

Ill STRUT,

AIR SHOULD

BCTHPACC,

LOW6

ISLAMD,M

Y.,u$A

BC

ADDCD

-

RCYOVLD

Al

nCOUIIILo.

SERIAL

NO.

TYPE

OROER

NO.

DESIGN

NO.

aas

SW

408

414

42a

432

44t

452

4as

474

4lb

498

4 St4

SIO

SPECIFICATION

NO.

4 WI

S24

TO CHECK FLUID

LEVEL

4 l/2

bS0

4 a/a

8SS

I.

nCM0VC

VALVE

CAP

FROM

HIGH

PItStURK

AIR

VALVC

(US

tBSS@-I).

4 I/4

sia

2.

SLOWLY

DlSCb4AR.t

ALL

AIR

BY Tm&lkC

SWWCL

MUTtTURw

COUk-

4

t/a

TCXCLDCXWISC)

WOTt@

RATC

OI

DlSCHAZI6C

It

CSTABLISMCO

BY

4

UOS

AYDUWI

SUIVCL

nut

IS

LOOSCMCO.

a I/@

@I7

S.

RCUOVL

fOMPLC?C

AIR

VALVE

ASBCYOLY

AND

FILLYTRU?

WITW

MIL-M-3604

(RCD

COLOR)

TO

LCVCL

Of

FlLLtR

HOLE

Wltn

STRUT

a s/4

641

111 NORMAL

OI)oUWD

*DSlflDN.

a 6/O

6aa

4.

RCPLACC

COMCLt

ft

AIR

VALVE

ASStM)LT

A*0

?lUH?CM

&OOY 10 lDO-

a v2

(1.1

110

‘4.

LBS.?OROUC

ANDJRCPLACL

LOCUWIRC

THCN

tNrLATC

S?RU?.

SCC

10

IWCATC

SYRU?.

a

a/u

710

b.

llCCLACf

AN0

TlQMlCN

VALVE

CAP.

a l/4

7s)

a

I/*

74s

TO

INFLATE

STRUT

3

7*t

2 7/o

82s

I.

RCHOVC

VAWL

CAP AHD

ATTACH

AIR

FILLCR

CWUCR TOHIGH

PRCt5URt

l

2 ad4

8s)

A111 VALVt.

2.

~0DS2.w

SWlVtL

NUT

[TURN

COUNTCRCLOCKWIS~)

4 MAX

OF 2VL

TURNS

2 we

089

A*0

INFLATC

STRUT

USING

Ala6288

-2

l RtfSUIC

UACC

ADJUST

2

I/2

*a*

PRCSSUIIC

IN ACCDROAkCC

Wltk

INtLA?ION

IktllUC?lONS.

2 B/8

S(I)

3.

TlCcctEM

SWIVTL

NU?

YO 30-70

IN.LBS.?ORQUC

(TURN

CLOCKWISCB

2 I/4

lOf4

RCWOVC

AIR

FILLER

CHUCK,CMCCX

FM

LtAKS

AN0

RC?LACL

VALVE

2

I/O

1092

C*r.

.2

1150

I 7/m

I2

22

I Y4

129s

Y4

i&St

FULLY

COUP

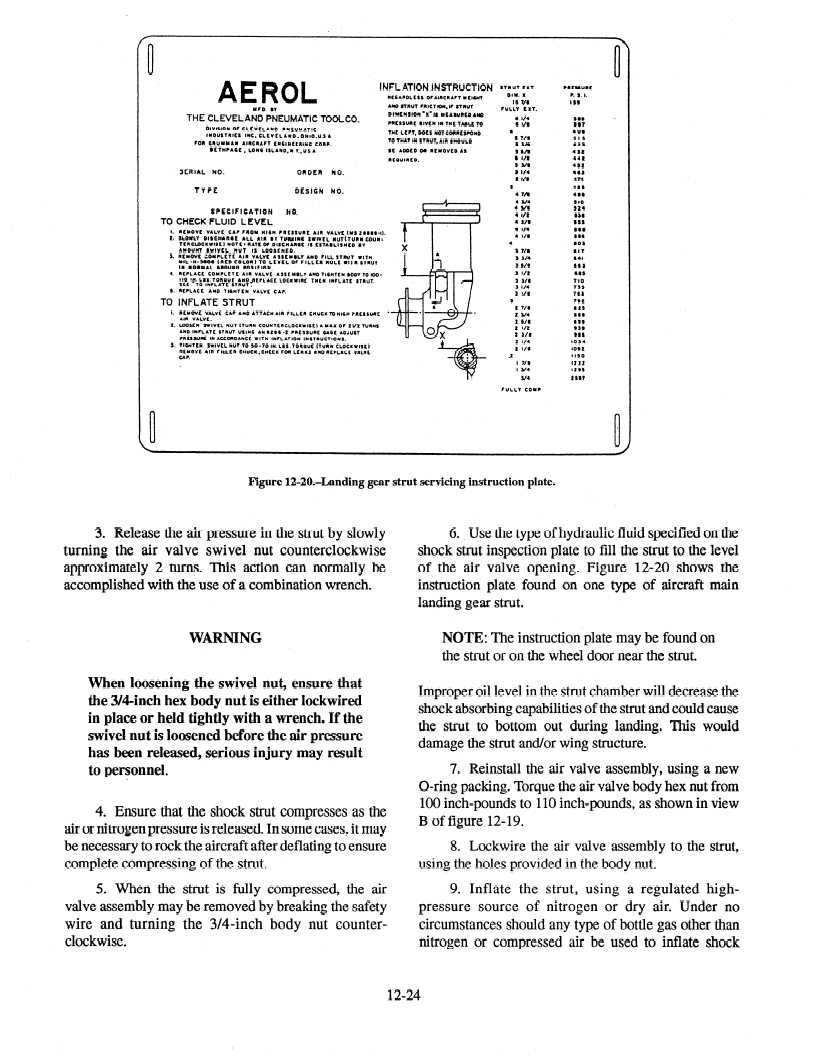

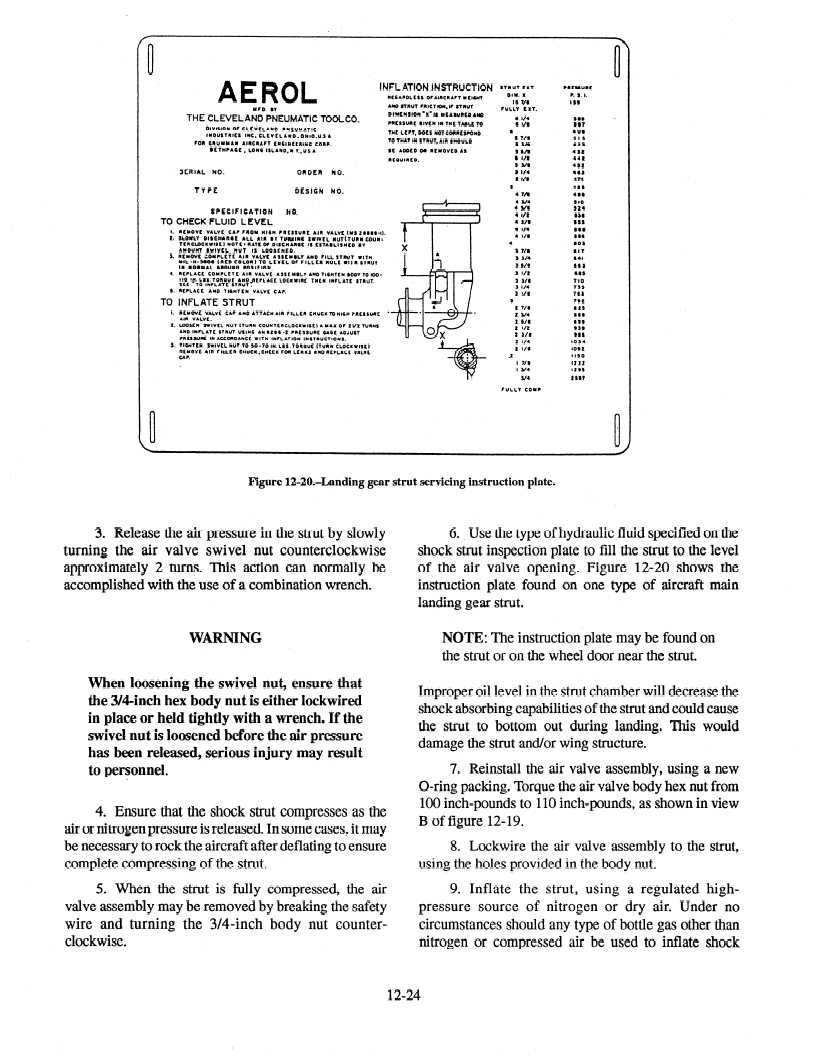

Figure 12020Aanding gear strut servicing instruction plate.

3. Release the air pressure in the strut by slowly

turning the air valve swivel nut counterclockwise

approximately 2 turns. This action can normally be

accomplished with the use of a combination wrench.

WARNING

When loosening the swivel nut, ensure that

the 3/4=inch hex body nut is either lockwired

in place or held tightly with a wrench. If the

swivel nut is loosened before the air pressure

has been released, serious injury may result

to personnel.

4. Ensure that the shock strut compresses as the

air or nitrogen pressure is released. In some cases,

it may

be necessary to rock the aircraft after deflating to ensure

complete compressing of the strut.

5. When the strut is fully compressed, the air

9. Inflate the strut, using a regulated high-

valve assembly may be removed by breaking the safety

pressure source of nitrogen or dry air. Under no

wire and turning the 3/4=inch body nut counter-

circumstances should any type of bottle gas other than

clockwise.

nitrogen or compressed air be used to inflate shock

6. Use the type of hydraulic fluid specified on the

shock strut inspection plate to fill the strut to the level

of the air valve opening. Figure 12-20 shows the

instruction plate found on one type of aircraft main

landing gear strut.

NOTE: The instruction plate may be found on

the strut or on the wheel door near the strut.

Improper oil level in the strut chamber will decrease

the

shock absorbing capabilities of the strut and could cause

the strut to bottom out during landing. This would

damage the strut and/or wing structure.

7. Reinstall the air valve assembly, using a new

O-ring packing. Torque the air valve body hex nut from

100 inch-pounds to 110 inch-pounds, as shown in view

B of figure 12-19.

8. Lockwire the air valve assembly to the strut,

using the holes provided in the body nut.

12-24