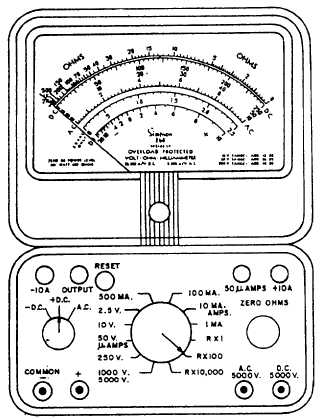

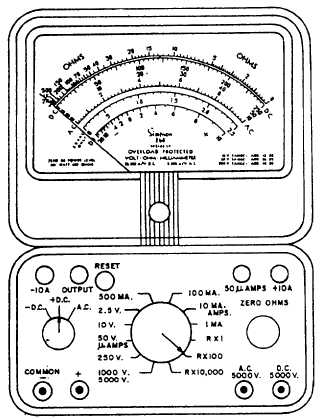

Figure 3-10.—A typical multimeter.

accordance with the applicable aircraft MIM.

Mechanical discrepancies are usually located during the

visual inspection in step 1.

Electrical malfunctions are located, with the

assistance of AEs, by tracing electrical power require-

ments throughout the affected system.

6. Correct the trouble. This step is accomplished

only after the trouble has been definitely located and

there is no doubt that your diagnosis is correct. Mal-

functions are usually corrected by replacement of units

or components, rigging and adjustments, and bleeding

and servicing.

NOTE: Always check the applicable MIM for

CAUTION, WARNING, and SAFETY notes

concerning maintenance procedures.

7. Conduct a final operational check. The affected

system must be actuated a minimum of five times, or

until a thorough check has been made to determine that

its operation and adjustments are satisfactory.

TESTING AND OPERATIONAL CHECKS

Aircraft systems tests and operational checks

should be performed under conditions as nearly

operational as possible. Such tests or checks should be

performed in accordance with the instructions outlined

in the applicable MIM. Make the operational checks in

the sequence outlined in the MIM. Any discrepancies

you find when performing a step should be corrected

before proceeding. The operational check and the

troubleshooting charts have been coordinated so that

malfunctions can be isolated in an efficient manner. If

the troubleshooting aids do not list the trouble being

experienced, you will have to study the system

schematics and perform the operational check. Use logic

and common sense in pinpointing the cause of the

malfunction. The test stand to be used in performing the

operational check must be capable of producing the

required flow and pressure required for proper

operation. Check all electrical switches and circuit

breakers, as well as hydraulic selector valves, for proper

position. Perform this check before applying external

electrical and hydraulic power. Perform all maintenance

in accordance with the MIM. Observe all maintenance

3-18