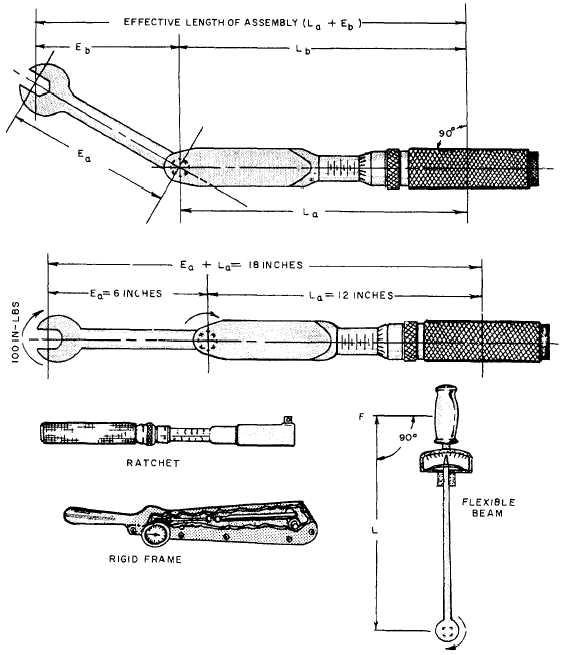

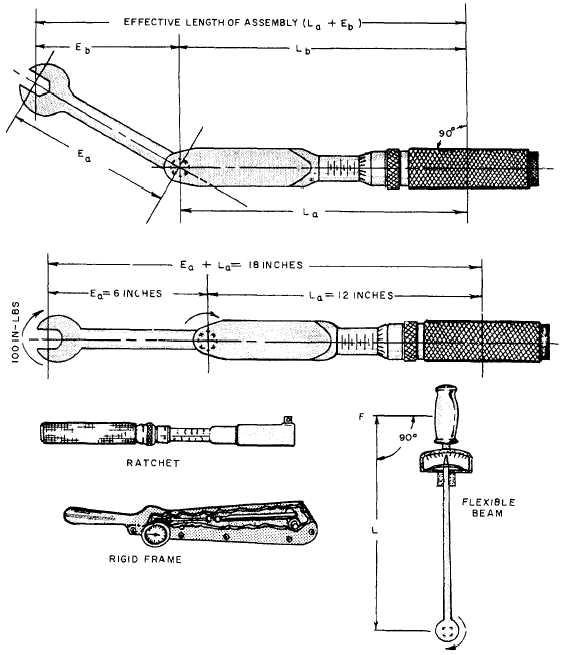

Figure 3-12.—Torque wrenches.

technical manual, these values take precedence over the

standard torque values provided in the Structural

Hardware Technical Manual, NAVAIR 01-1A-8.

Separate torque tables and torquing considerations

are provided in NAVAIR 01-1A-8 for the large variety

of nuts, bolts, and screws used in aircraft construction.

You should use this manual when specific torque values

are not provided as a part of the removal/replacement

instructions.

To obtain values in foot-pounds, divide inch-pound

values by 12. Do not lubricate nuts or bolts except for

corrosion-resistant

instructed to do so,

first if possible. When space considerations make it

necessary to tighten the fastener by rotating the bolt

head, approach the high side of the indicated torque

range. Do not exceed the maximum allowable torque

value. Maximum torque ranges should be used only

when materials and surfaces being joined are of

sufficient thickness, area, and strength to resist

breaking, warping, or other damage.

For corrosion-resisting steel nuts, use the torque

values given for shear-type nuts. The use of any type of

drive-end extension on a torque wrench changes the dial

steel parts or where specifically

reading required to obtain the actual values indicated in

Always tighten by rotating the nut

the torque range tables. See figure 3-12.

3-21