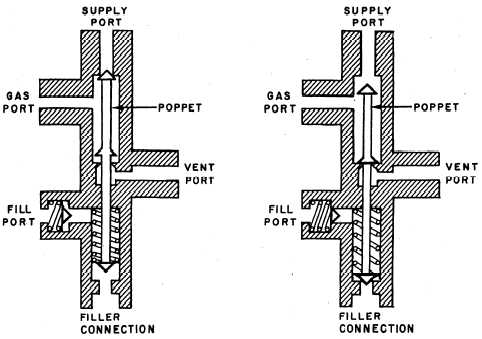

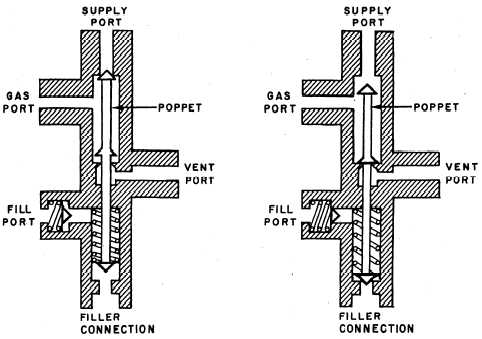

Filler Valve

The filler valve is a combination filler, vent,

and buildup valve. The filler portion of the valve

is essentially a spring-loaded check valve (fig. 4-8).

When the servicing hose of the LOX cart is

coupled to the filler connection, the poppet is

displaced. This seals the supply port and allows

container pressure to be relieved through the vent

port. At the same time, oxygen flows through the

filler connection and fill port to the container.

When the container is full, the liquid flows from

the container through the gas port and then

through the vent port. In the normal position, the

spring in the filler connection holds the poppet

in place, forming a gastight seal. There is a check

valve in the fill port that acts as a backup seal in

the event the filler connection develops a leak. The

vent port is also sealed in this position, allowing

the gaseous boiloff (from the top of the container)

to flow through the gas port to the supply port

and into the oxygen system.

Pressure Control Valve

The pressure control valve used on most

converters is a combination opening and closing

valve (two valves contained within one housing).

These valves are controlled by spring-loaded

bellows. The pressure closing valve is spring-

loaded open and the pressure opening valve

is spring-loaded closed. The pressure closing

valve maintains operating pressure within the

converter. The pressure opening valve controls

the flow of gaseous oxygen into the supply

line. If the pilot’s demand for oxygen becomes

greater than the capability of the pressure

opening valve to deliver, there is a differential

check valve that opens and allows liquid oxygen

to flow directly into the supply line. It is

transformed into gaseous oxygen during its

passage through the oxygen system supply

lines.

Relief Valves

A relief valve is provided in the converter to

relieve excessive pressure buildup in the event of

a malfunction in the pressure control valves. It

also relieves normal pressure buildup when the

system is not in use. This normal buildup pressure

is caused by heat entering the system, and will

cause a loss of 10 percent of the systems capacity

every 24 hours. As an example, approximately 1

liter of loss will be experienced from a 10-liter

converter.

Figure 4-8.—Filler valve.

4-14