warm air entering the dehydrator. The heating of

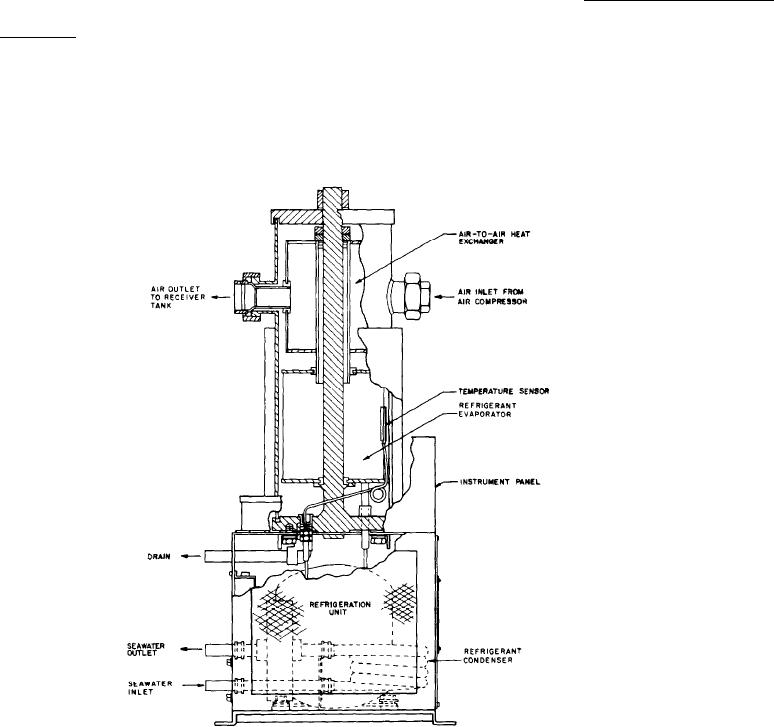

in figure 7-27 is a REFRIGERATION DE-

the air serves to reduce thermal shock as the air

H Y D R A T O R or REFRIGERATED AIR

enters the system. The exiting dry air flows into

DRYER. This unit removes water vapor entrained

the receiver for availability to the ship's air system.

in the stream of compressed air by causing the

water to condense into a liquid that is heavier than

air. Air flowing from the separator/holding tank

DESICCANT AIR DEHYDRATOR

first passes through the air-to-air heat exchanger,

(TYPE II)

where some of the heat of compression is removed

from the airstream. The air then moves through

Desiccant is a drying agent. More practically,

the evaporator section of the dehydrator, where

desiccant is a substance with a high capacity

the air is chilled by circulating refrigerant. In this

to remove (adsorb) water or moisture. It also has

unit, the airstream is cooled to a temperature that

a high capacity to give off that moisture so the

is below the dew point. This will cause the water

desiccant can be reused. DESICCANT-TYPE

vapor in the air to condense so it can be removed

DEHYDRATORS are basically composed of

by the condensate drain system. After leaving the

cylindrical flasks filled with desiccant.

evaporator section, the dehydrated air moves

upward through the cold air side of the air-to-air

Compressed air system dehydrators use a pair

heat exchanger. In the air-to-air heat exchanger,

of desiccant towers. One tower is in service

the dehydrated air is raised in temperature by the

Figure 7-27.--Dehydrator (type I).

7-26