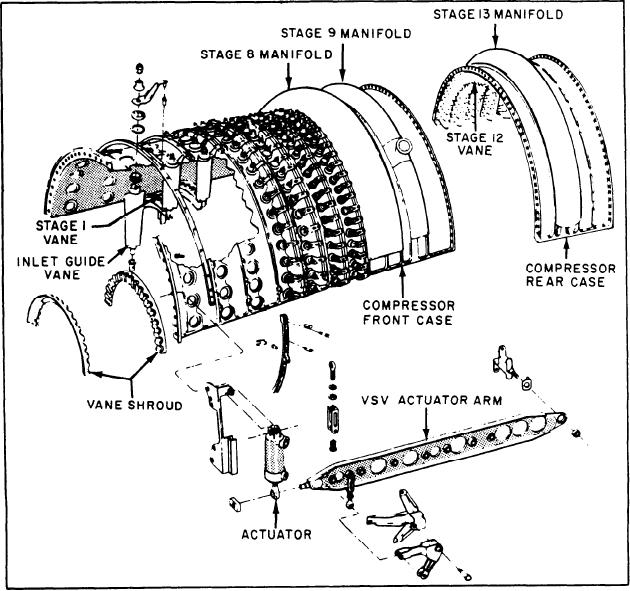

Figure 2-25.--Compressor stator.

clarity, figure 2-25 shows only the top two

Three bleed manifolds are welded to the stator

casings. Eighth-stage air, used for sump seal

sections and the major components of the

pressurization and cooling, is extracted from

compressor stator. The front casing contains

inside the annulus area at the tips of the hollow

the IGVs and stages 1 through 11. The IGVs and

eighth-stage vanes. Ninth-stage air, used for

the first six stages are variable to provide

stall-free operation. The variable vanes are

PT cooling, PT forward seal pressurization, and

PT balance piston cavity pressurization, is

actuated by a pair of master levers (one on each

extracted from between the ninth-stage vanes

side). The aft end of the master levers are

through holes in the vane bases. Thirteenth-stage

attached to pivot posts at about the 10th stage

air, used for cooling the second-stage HP turbine

on each side of the casing. Each of the lever's

nozzle, is extracted from between the thirteenth-

forward ends is positioned by a hydraulic actuator

stage vanes through holes in the vane bases.

which uses fuel oil as the actuating medium. The

operation of the IGVs and variable stator vanes

REAR FRAME.--The compressor rear frame

(VSVs) are covered later in this chapter. The

(fig. 2-26) has an outer case, a hub containing

remaining vanes are stationary. The rear casing

the B sump, and 10 struts attaching the hub to

contains the 12th through the 16th stages, which

the outer case. The outer case supports the

are also stationary.

2-22