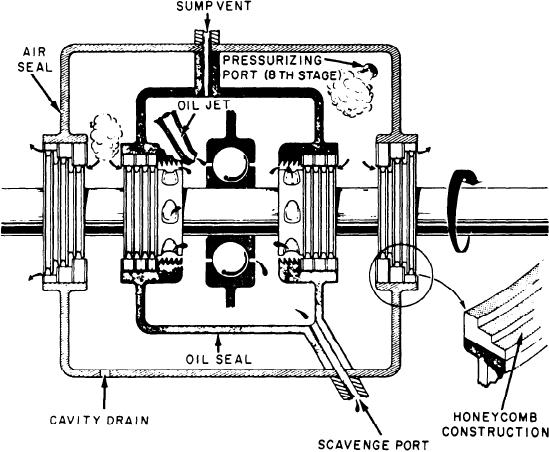

Figure 2-50.--Bearing sump.

outlet fitting on the enclosure base, and is returned

Lube Oil Flow

to the LOSCA.

At the LOSCA the oil passes through the

Lube oil is gravity fed from the oil tank in the

scavenge filters to the scavenge check valve.

LOSCA through the ship's piping to an inlet

The oil then goes through the oil cooler where it

fitting in the enclosure base. It is then fed to the

is cooled by the MRG (2190 TEP) lube oil. The

inlet of the supply element of the lube and

cooled oil is then routed to the oil tank for storage

scavenge pump. From the supply element of the

and deaerating.

pump, the oil passes through the supply duplex

filter. It then goes through a check valve and

IGNITION SYSTEM

into a supply manifold. From the supply

manifold, the oil is distributed to the four

The ignition system provides ignition to start

sumps and the TGB. Each end of the sump has

combustion in the engine. It has ignition exciters

a labyrinth/windback oil seal and a labyrinth air

and two spark igniters located in the combustor.

seal (fig. 2-50). This is to prevent oil leakage from

The system is actuated by an electronic signal

the sumps. The cavity between the two seals is

during the engine start sequence. It is generated

pressurized by eighth-stage air ejectors. The

either manually by the operator or by the

pressure in the cavity is always greater than the

electronic timing controls. The engine must reach

pressure inside the sump. Air flowing from the

a speed of 1,200 rpm prior to ignition; then, if

cavity, across the oil seal, prevents oil from

performing a manual start, you must energize the

leaking across the seal.

igniters before opening the fuel valves. When

you start the engine in the automatic mode, the

The scavenge oil is drawn in from the sumps

fuel valves will not open unless the igniters are

and TGB by the five scavenge elements of the

already functioning. This prevents excess fuel

pump. It passes through the pump, through an

2-44