Use 135 x 7 needles with machines set with

1/4-inch clearance under the presser foot, and

135 x 17 needles with those set with 3/8-inch

clearance (lift).

Adjustments

Adjustments to the 211 W 151 are basically

the same as for 111 W 151. These adjustments

are discussed in the following text.

SETTING THE NEEDLE BAR.— Place the

needle bar up into the needle bar holder as far

as possible. Hold in this position and turn the

balance wheel toward the operator until the needle

bar is at its lowest position. When in this position,

set the bar so the upper timing mark is just visible

below the needle bar frame, and tighten the needle

bar connecting stud pinch screw.

In case the needle bar does not have timing

marks, set the machine to zero stitches per inch

and place the needle bar up in the holder as far

as possible. Turn the balance wheel by hand until

the bar is at its lowest position. After reaching

the lowest position of the needle bar, continue

turning the balance wheel toward the operator

until it reaches 3/32 inch above its lowest point,

then set the eye of the needle 1/16 inch below the

point of the sewing hook.

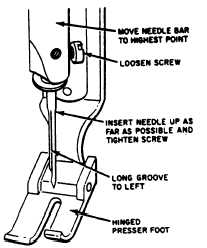

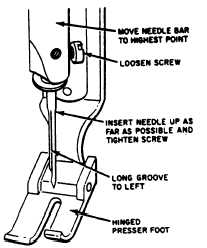

SETTING THE NEEDLE.— To set the nee-

dle, insert the needle shank as far as possible into

the needle bar with the long groove of the needle

to the left and tighten the screw. (See figure 9-33.)

240.82

Figure 9-33.—Setting the needle.

240.83

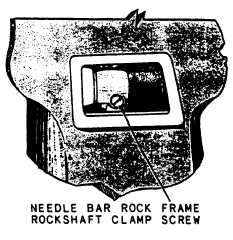

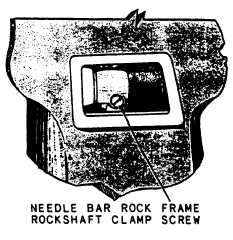

Figure 9-34.—Needle bar rock frame rockshaft damp screw.

RELATIVE POSITION OF’ NEEDLE BAR

AND PRESSER BAR.— To set the relative

position of the needle bar to the presser bar,

loosen the needle bar rock frame rockshaft clamp

screw, which is located behind the cover plate on

the front upright position of the arm (fig. 9-34).

Set the needle bar so the distance between the

needle bar and presser bar is 17/32 inch. Retighten

the clamp screw.

NOTE: A handy tool for this adjustment

can be manufactured locally from a thin

piece of metal stock filed to exactly

17/32-inch width. This gauge should be

placed between the two bars while the

clamp screw is being tightened. This

enables the operator to keep pressure on

the loose needle bar.

ADJUSTMENT HEIGHT OF SEWING

HOOK.— Before attempting to adjust the

height of the sewing hook, it is necessary to

make a feeler gauge for testing the height.

This gauge can be made of 0.032-inch shim stock,

or a regular feeler gauge can be cut or trimmed

down so it will fit in the small groove in the

throat plate, which retains the bobbin case stop

finger.

If, after testing,

the hook height is

unsatisfactory, turn the balance wheel so the two

setscrews in the bottom of the hook are accessible;

loosen them with an Allen wrench. Remove the

cloth washer from the bobbin case and turn the

hook until the height adjusting screw is directly

9-27