at the air lines before changing grinding wheels,

needles, chisels, or other cutting or drilling bits.

The air hose must be suitable to withstand the

pressure required for the tool. A leaking or

defective hose should be removed from service.

The hose should not be laid over ladders, steps,

scaffolds, or walkways in such a manner as to

create a tripping hazard. Where the hose is run

through doorways, the hose should be protected

against damage by the doors' edges. The air hose

should generally be elevated over walkways or

working surfaces in a manner to permit clear

passage and to prevent damage to it.

All portable pneumatic grinders must be

equipped with a safety lock-off device. A safety

lock-off device is any operating control that

requires positive action by the operator before

the tools can be turned on. The lock-off device

must automatically and positively lock the

throttle in the OFF position when the throttle is

released. Two consecutive operations by the

same hand are required, first to disengage the

lock-off device and then to turn on the throttle.

The lock-off device should be integral with the

tool. It should not adversely affect the safety or

operating characteristics of the tools, and it

should not be easily removable. Devices, such as

a "dead-man control," that do not automatically

and positively lock the throttle in the OFF

position when the throttle is released are not

safety lock-off devices.

For detailed information on safety precautions, see

Navy Occupational Safety and Health (NAVOSH)

Program Manual for Forces Afloat, OPNAVINST

5100.19 (latest series).

SAFETY PRECAUTIONS FOR USE WITH

PNEUMATIC TOOLS—SPECIFIC

In operating or maintaining air-driven tools, take

the following precautionary measures to protect

yourself and others from the damaging effects of

compressed air:

Inspect the air hose for cracks or other defects;

replace the hose if found defective.

WARNING

Before opening the control valve, see that

nearby personnel are not in the path of the

airflow. Never point the hose at another person.

Open the control valve momentarily before

connecting an air hose to the compressed air

outlet. Then, make sure the hose is clear of water

and other foreign material by connecting it to the

outlet and again opening the valve momentarily.

Stop the flow of air to a pneumatic tool by

closing the control valve at the compressed air

outlet

before

connecting,

disconnecting,

adjusting, or repairing a pneumatic tool.

REVIEW QUESTIONS

Q33.

Identify different types of portable pneumatic

power tools.

Q34.

What are rotary and needle sanders used for?

Q35.

List the safety precautions that apply to

portable pneumatic power tools.

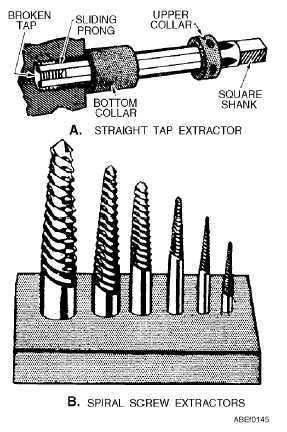

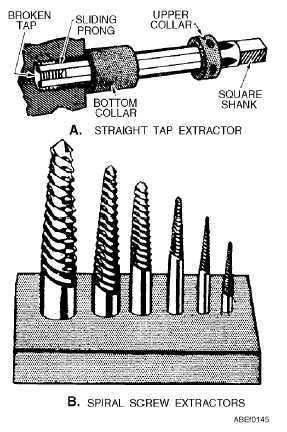

SCREW AND TAP EXTRACTORS

LEARNING OBJECTIVE: State the purpose

of screw and tap extractors.

Screw extractors are used to remove broken screws

without damaging the surrounding material or the

threaded hole. Tap extractors are used to remove broken

taps (fig. 1-68, view A).

1-42

Figure 1-68.—Screw and tap extractors.