The combination pliers are handy for holding or

bending flat or round stock. The long-nosed pliers are

less rugged, and break easily if you use them on heavy

jobs. Long-nosed pliers, commonly called needle-nose

pliers, are especially useful for holding small objects in

tight places and for making delicate adjustments. The

round-nosed kind are handy when you need to crimp

sheet metal or form a loop in a wire. The diagonal

cutting pliers, commonly called "diagonals" or "dikes,"

are designed for cutting wire and cotter pins close to a

flat surface and are especially useful in the electronic

and electrical fields. The duckbill pliers are used

extensively in aviation areas.

Here are two important rules for using pliers:

1.

Do not make pliers work beyond their capacity.

The long-nosed kind is especially delicate. It is

easy to spring or break them, or nick their

edges. After that, they are practically useless.

2.

Do not use pliers to turn nuts. In just a few

seconds, a pair of pliers can damage a nut.

Pliers must not be substituted for wrenches.

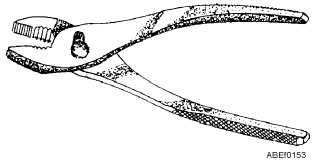

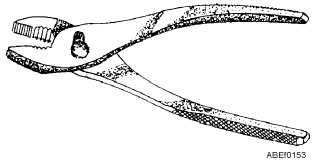

SLIP-JOINT PLIERS

Slip-joint pliers (fig. 1-43) are pliers with straight,

serrated (grooved) jaws, and pivot where the jaws are

fastened together to move to either of two positions to

grasp small- or large-sized objects better.

Slip-joint combination pliers are pliers similar to

the slip-joint pliers just described but with the

additional feature of a side cutter at the junction of the

jaws. This cutter consists of a pair of square-cut

notches, one on each jaw, which act like a pair of shears

when an object is placed between them and the jaws

closed.

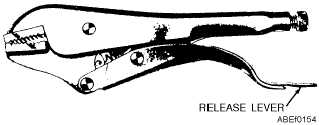

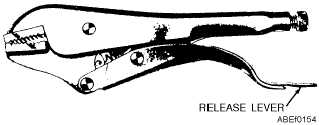

WRENCH PLIERS

Wrench pliers (visegrips) (fig. 1-44), can be used

for holding objects regardless of their shape. A screw

adjustment in one of the handles makes them suitable

for several different sizes. The jaws of wrench pliers

may have standard serrations such as the pliers just

described, or they may have a clamp-type jaw. The

clamp-type jaws are generally wide and smooth and are

used primarily when working with sheet metal.

Wrench pliers have an advantage over other types

of pliers in that you can clamp them on an object and

they will stay. This will leave your hands free for other

work.

A craftsman uses this tool a number of ways. It may

be used as a clamp, speed wrench, portable vise, and for

many other uses where a locking, plier-type jaw may be

used. These pliers can be adjusted to various jaw

openings by turning the knurled, adjusting screw at the

end of the handle (fig. 1-44). Wrench pliers can be

clamped and locked in position by pulling the lever

toward the handle.

CAUTION

Wrench pliers should be used with care,

since the teeth in the jaws tend to damage the

object on which they are clamped. They should

not be used on nuts, bolts, tube fittings, or other

objects that must be reused.

WATER-PUMP PLIERS

Water-pump pliers were originally designed for

tightening or removing water-pump packing nuts. They

were excellent for this job because they have a jaw

adjustable to seven different positions. Water-pump

pliers (fig. 1-45) are easily identified by their size, jaw

teeth, and adjustable slip joint. The inner surface of the

jaws consists of a series of coarse teeth formed by deep

1-28

Figure 1-43.—Slip-joint pliers.

Figure 1-44.—Wrench pliers.

Figure 1-45.—Water-pump pliers.