CHAPTER 6

M61A1 GUN INSTALLATION

Gun systems installed in high-speed aircraft must

meet demanding performance requirements and

provide firepower. The General Electric M61A1

20-mm automatic gun system, installed in the F-14 and

F/A-18 aircraft, meets these requirements.

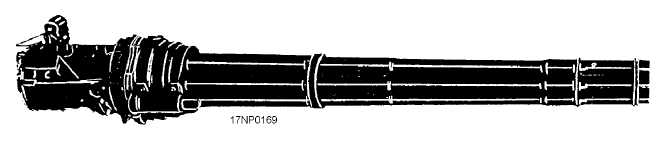

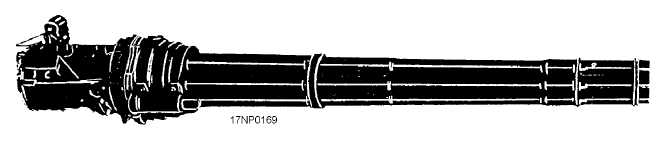

The M61A1 (fig. 6-1) is a six-barrel, rotary-action,

automatic gun based on the machine-gun design of

Richard J. Gatling. The gun consists of a revolving

cluster of barrels. Each barrel is fired once per

revolution. The M61A1 automatic gun is hydraulically

driven, electrically controlled, and can fire M50 and

PGU-series ammunition at 4,000 to 7,200 rounds per

minute. As installed in Navy aircraft, the gun has a pilot

selectable firing rate of either 4,000 (GUN LOW) or

6,000 (GUN HIGH) rounds per minute. It is designed

for either air-to-ground or air-to-air gunnery missions.

Ammunition is supplied to the M61A1 gun by an

ammunition handling and storage system that functions

within a specific aircraft. The system uses an endless

conveyor that transports 20-mm ammunition from the

ammunition drum to the gun. The conveyor then returns

the expended cases and unfired rounds to the

ammunition drum.

Although the physical location of components

varies between different aircraft gun installations, the

function and description of the components are

essentially the same.

M61A1 AUTOMATIC GUN

LEARNING

OBJECTIVE:

Identify

the

components of the M61A1 automatic gun and

recognize the operating principles.

The primary parts of the gun are the barrels,

housing assembly, and rotor assembly. The following

paragraphs

contain

a

description

of

each

gun

component and an explanation of how each component

works. Figure 6-2 shows an exploded view of the gun

components, and figure 6-3 shows the gun component

locations. As each component is discussed, you should

look at these figures.

GUN COMPONENTS

The primary parts of the gun are described in the

following paragraphs.

Muzzle clamp assembly. The muzzle clamp

assembly is positioned at the outer end of the barrels. It

restrains individual barrel movement during firing. It is

positioned against the flange on the barrels and secured

by the pressure of the self-locking nut assembly against

the opposite side of the shoulders.

Mid-barrel clamp assembly. The mid-barrel

clamp assembly is positioned near the center of the

barrels. The clamp tabs are engaged in the slots of the

stop shoulders on the barrels. Secure the clamp in this

position by rotating the locating disk to the locked

position. The direction of rotation of the gun and barrel

hue prevents the clamp from unlocking. Insert a cotter

pin through the locking disk and clamp plate as an

additional safety measure.

Barrels. The M61A1 automatic gun has six rifled

barrels. The stub rotor attached to the rotor body

supports them. The three rows of interrupted locking

lugs on the barrel engage similar interrupted locking

lugs in the rotor to secure the barrel. There are three

6-1

Figure 6-1.—M61A1 automatic gun.