protects itself by permitting such articles to sink into, or

can also cause some bearings to fail from oil starvation,

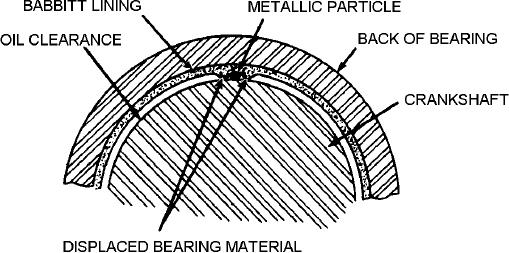

embed in, the bearing lining material. If the bearing

as the oil pump can deliver only so much oil. If the oil

were too hard to allow this, the particles would simply

clearances are excessive, most of the oil will pass

lie on the surface. They would scratch the shaft journal

through the nearest bearings. There won't be enough for

and probably gouge out the bearing. This, in turn,

the more distant bearings; these bearings will probably

would cause overheating and rapid bearing failure.

fail from lack of oil. An engine with excessive bearing

Thus, the bearing material must be soft enough for

oil clearances usually has low oil pressure; the oil pump

adequate embedability.

cannot build up normal pressure because of the

excessive oil clearances in the bearings.

Conformability.--This is associated with embed-

On the other hand, if oil clearances are not

ability. It refers to the ability of the bearing material to

sufficiently great, there will be metal-to-metal contact

conform to variations in shaft alignment and journal

between the bearing and shaft journal. Extremely rapid

shape. For example, suppose a shaft journal is slightly

wear and quick failure will result. Also, there will not

tapered. The bearing under the large diameter will be

be enough oil throw-off for adequate lubrication of

more heavily loaded. If the bearing material has high

cylinder walls, pistons, and rings.

conformability, it will flow slightly away from the

heavily loaded areas to the lightly loaded areas. This

BEARING REQUIREMENTS.--Bearings must

redistributes the bearing material so that the bearing is

be able to do things other than carry the loads imposed

more uniformly loaded. A similar action takes place

on them.

when foreign particles embed in the bearing. As they

Load-Carrying Capacity.--Modern engines are

embed, they displace bearing material, thus producing

lighter and more powerful. They have higher

local high spots (fig. 3-60). However, with high

compression ratios and thus impose greater bearing

conformability, the material flows away from the high

loads.

spots. This tends to prevent local heavy loading that

could cause bearing failure.

Fatigue Resistance.--When a piece of metal is

repeatedly stressed so that it flexes or bends, it tends to

Corrosion Resistance.--The bearing materials

harden and ultimately breaks; this is called fatigue

must be resistant to corrosion, since some of the

failure. Repeatedly bending a piece of wire or sheet

by-products of combustion may form corrosive

metal will demonstrate fatigue failure. Bearings are

substances.

subjected to varying loads and are repeatedly stressed.

Wear Rate.--The bearing material must be

The bearing material must be able to withstand these

sufficiently hard and tough so that it will not wear too

varying loads without failing from fatigue.

fast. At the same time, it must be soft enough to permit

Embedability.--This term refers to the ability of a

good embedability and conformability.

bearing to permit foreign particles to embed in it. Dirt

BEARING MATERIALS.--The bearing back is

and dust particles enter the engine despite the air

usually made of steel. The lining material is a

cleaner and oil filter. Some of them work onto the

combination of several metals, mixed or alloyed, to

bearings and are not flushed away by the oil. A bearing

ASf03060

Figure 3-60.--Effect of a metallic particle embedded in bearing material (Babbit lining).

3-41