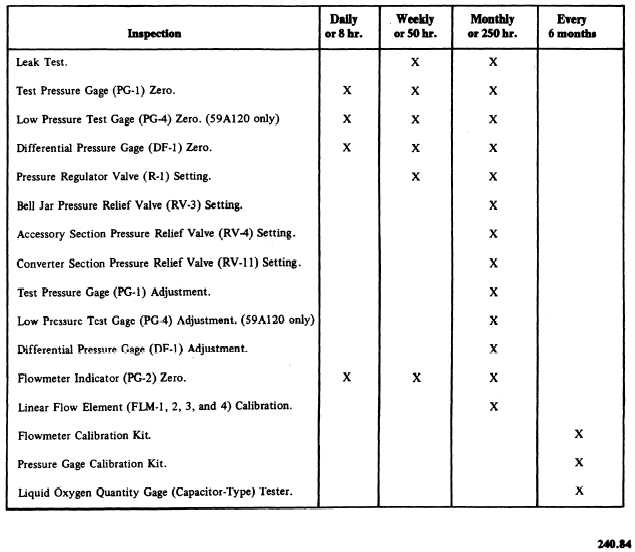

Table 1-2 lists, by calendar and operating time, the periodic inspections to be performed in the interest of efficient operation.

CLEANING

A clean test stand not only looks neat but it gives better service. A clean stand is essential if leaks are to be located in a timely manner. All external parts of the test stand must be cleaned with oxygen systems cleaning compound Mil- C-81302, Type 1.

When you clean the test stand, be sure the test adapters and connection hoses stored in the accessory tray are also cleaned.

If the front panel of the test stand must be removed for any reason, you must ensure that all gage tester surfaces are free from dust and any other foreign matter. The best way to clean these surfaces is to use clean, low-pressure dry air (about 10 psi is recommended). To clean the interconnecting piping, hoses, and fittings on the test stand, you should use clean, dry air pressure not to exceed 160 psig.

Type 1 Freon is recommended for cleaning the terminals of the Liquid Oxygen Quantity Gage Tester (capacitor type) test stand.

The bell jar on the 59A120 test stand has a sealing O-ring. This O-ring must be cleaned with distilled water and lubricated with alight coat of lubricant Mil G 27617.

Table 1-2. - Periodic Inspection Chart