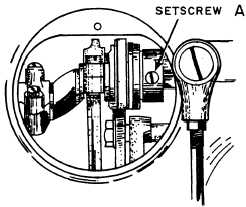

Figure 4-19. - Feed-driving eccentric.

the timing and adjustment procedures for the 31-15 sewing machine.

DISASSEMBLY AND REASSEMBLY OF THE 1ll W 155 SEWING MACHINE

You probably will never need to take the lll W 155 class sewing machine completely apart, but you may need to replace some parts. Therefore, you need to know the procedures for disassembling and reassembling the 111 W 155 sewing machine.

The following are some helpful hints that you should remember while working on disassembly and reassembly of any sewing machine:

All sewing machine screws have a case - hardened surface, which must be removed by grinding should it become necessary to use an easyout to remove the screw.

Using grinding compound is recommended when you are replacing parts that attach to a shaft. Place a small amount of grinding compound on the shaft and rotate the part on the shaft until it moves freely. (Remove all grinding compound before you reassemble the parts.)

Oiling is a must in the reassembly of parts. A generous amount of 10W mineral oil is justified when you are replacing parts.

There is one screw (thread take-up lever retaining screw) on the drop-feed type of sewing machine that has a left-hand thread. It is found # in the face of the machine. This screw is removed by turning it clockwise.

DISASSEMBLY

In this section we discuss the purpose of each part of the 111 W 155 sewing machine and the disassembly and reassembly of each part. Before disassembling any sewing machine, you should select and clean an area that will allow you to work on your project with a minimum of interruptions. Select your tools, cleaning solvents, and a parts breakdown list; then you are ready to begin your project.

Arm Cap

The arm cap (figure 4-2 [B]) permits inspection of the mechanism of the arm. The arm mechanism is exposed when the arm cap is moved to one side or the other. Remove the arm cap by unscrewing the holding screw and spring washer that attach it to the machine arm; then lift the arm cap from the machine.

Faceplate

The faceplate (figure 4-2 [F]) permits inspection and minor adjustment of the parts in the machine face. The mechanism of the machine face is exposed when the faceplate is moved to one side or the other. Remove the faceplate by removing the thumbscrew at the top of the plate; then move the plate slightly to the left to clear the metal projection at the lower left corner and lift the faceplate from the machine.

Knee Lifter Lifting Lever Hinge Screw

The knee lifter lifting lever hinge screw (figure 4-11 [E]) acts as a hinging point for the knee lifter lifting lever. It is removed from the machine by unscrewing it.

Knee Lifter Lifting Lever

The knee lifter lifting lever (figure 4-11 [F]) acts as an extending arm that attaches the presser bar lifting releasing lever bracket to the knee lifter lifting lever. It carries the motion from the knee lifter lifting lever to the presser bar lifting releasing lever bracket. Remove the knee lifter lifting lever by grasping and moving it outward from the machine.

Continue Reading