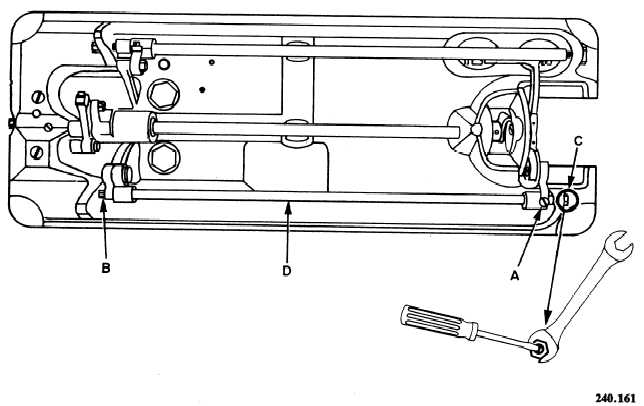

Set the sewing machine to its maximum stitch length. Loosen the feed-driving rockshaft crank pinch screw (figure 4-18 [A]). Rotate the feed-driving rockshaft (figure 4-18 [D]) so that the feed dog's movement is an equal distance from the front and rear of the throat plate slots. After you do this, retighten the feed-driving rockshaft crank pinch screw.

Setting Side Play of Feed Dogs

Loosen the adjusting screw locknuts (figure 4-18 [B]). Adjust the feed-driving rockshaft (figure 4-18 [D]) to center the side play of the feed dogs by turning the adjusting screws (figure 4-18 [C]) left or right as needed; then retighten the adjusting screw locknuts. Be sure the adjusting screw locknuts hold the feed-driving rockshaft snugly in place without binding.

Timing the Feed-Driving Eccentric

Timing the feed-driving eccentric is accomplished as follows: -

1. Set the stitch regulator to its lowest point. This gives the operator the maximum stitch length of 7 SPI.

2. Rotate the balance wheel toward the operator until the feed dogs complete their movement aft and before they begin to drop. At this point the needle must be entering the material being sewn. If this doesn't occur, the following trial-and-error sequence must be made:

Open the cover located on the rear of the uprise. Rotate the balance wheel until the feed-driving eccentric setscrew becomes visible (figure 4-19 [A]). Loosen this screw. Now place your finger or a screwdriver on the feed-driving eccentric to hold the eccentric in place, and rotate the balance wheel a short distance. Retighten the feed-driving eccentric setscrew. Continue this procedure until the sewing machine complies with step 2.

Setting the Presser Bar

Turn the balance wheel until the feed dogs are just below the top of the throat plate. Loosen the presser bar guide lever setscrew (figure 4-16 [C]). Push the presser firmly against the throat plate, aligning the slot between the toes of the presser foot with the hole in the throat plate. Tighten the presser bar guide lever setscrew. This completes

Figure 4-18. - Centering feeding action.

Continue Reading