Turn the leakage selector valve to LOW RANGE. No leakage should be indicated on the low-range rotameter. Return the leakage-selector valve to HIGH RANGE and the inlet pressure on/off valve to the ON position.

Slowly open the low-pressure regulator until the regulated low-pressure gage indicates 160 psig. (The N2 input pressure gage should read its gage guard pressure of 145 5 psig). Turn the inlet pressure on/off valve to OFF. No leakage should be indicated on the high-range leakage rotameter. Turn the leakage selector valve to the LOW-RANGE position. No leakage should be indicated on the low-range leakage rotameter. Use the system bleed valve to decrease the pressure to 70 psig. You must turn the low-pressure regulator counterclockwise until 70 psig is maintained. Leave the test stand in this condition; it is set up for you to perform your next leakage test.

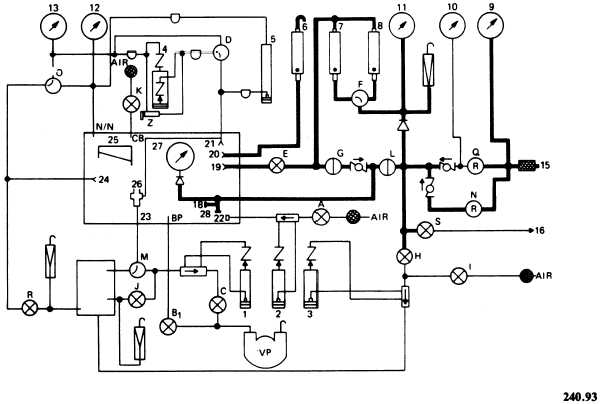

ROTAMETER SYSTEM

The purpose of the rotameter system is to determine leakage or to make adjustments to items that require bleed adjustments, such as the 20004 miniature regulator. The system consists of two in-system rotameters and one overload rotameter as shown in figure 2-6. The source of pressure for the in-system rotameters is the low-pressure regulator (N). You receive your source of pressure for the overboard rotameter from the item under test.

PRESSURIZING THE ROTAMETER SYSTEMS

To use the rotameter system, turn the inlet pressure on/off valve (L) to ON.

NOTE: Before you pressurize the rotameter systems, be sure the leakage selector valve (F) is in the HIGH position. This valve should always be in the HIGH position unless you are using the low-range rotameter to read low readings.

Turn the leakage on/off valve (G) to ON and the inlet pressure on/off valve to OFF. Look at your high-range leakage rotameter. If no leakage is indicated, turn your leakage selector valve (F) to the LOW RANGE position. Check your low-range leakage rotameter for leaks. In both leakage tests if the small ball rises in the

Figure 2-6. - Model 1172AS100 rotameter system.

Continue Reading