• LOADING FROM A TRUCK ON THE DOCK.

Rig a direct line from the truck to the filling

connection. With this method, a pump on the truck is

used to boost the oil from the truck to the filling

connection.

CAUTION

When loading from struck on the dock, use

caution to ensure that the pressure from the

truck to the lube oil system is not enough to

cause damage to hose, piping, or pumps.

When the system is taking on lube oil, a vent is

not necessary, because the system is vented through

the tank to the overflow tank. The valves from the

tank to the overflow tank are locked open during this

operation. To allow for expansion, tanks should not be

filled beyond 90% capacity.

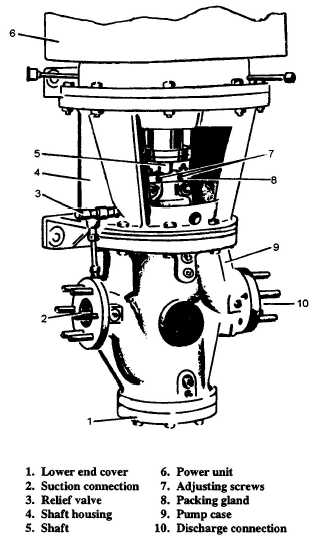

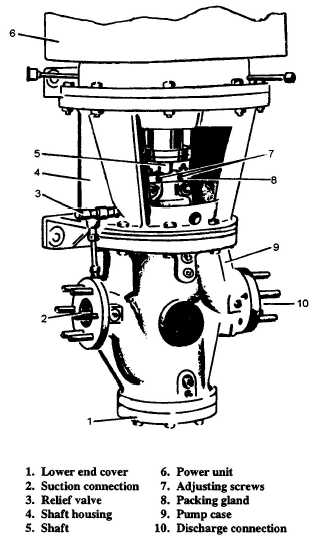

Figure 6-2.—Typical rotary-screw lube oil pump.

Lube Oil Pumps

Numerous lube oil pumps are installed on Navy

ships, and it would be nearly impossible to cover each

one. This manual will cover an older pump, the De

Laval 31P156.

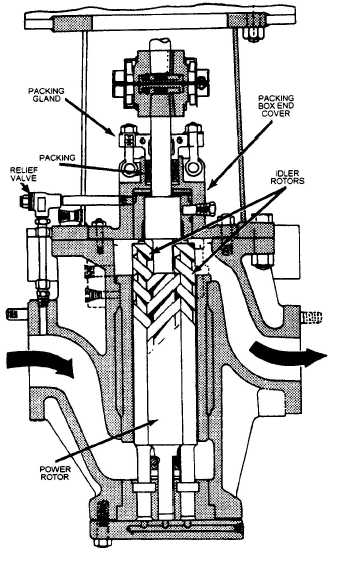

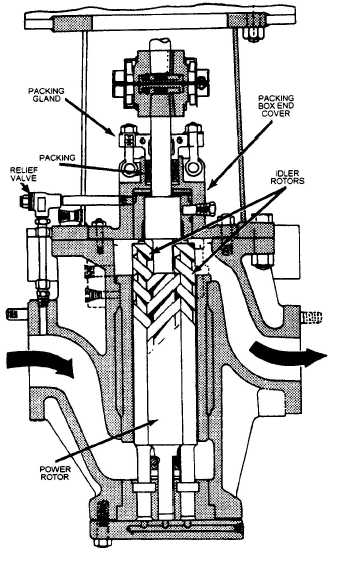

The De Laval 31P156 is a vertical, single-stage,

positive displacement, rotary-screw pump (figs. 6-2 and

6-3). The pump consists of a power rotor (which moves

the oil), two idler rotors (for sealing), the housing,

thrust elements, shaft packing, and piping con-

nections.

When the pump is started for the first time or

after a long period of idleness, follow the instructions

for initial starting, given below.

Figure 6-3.—Rotary-screw pump (cutaway).

6-3