sure-relief valve (set at 4 psi), a pressure gage, and a

portable inertness analyzer connection.

A fixed eductor is installed in the cofferdam to

remove any seawater or gasoline that might escape

from the storage tanks. The eductor is fitted with two

suctions: one near the centerline at the forward end

of the cofferdam and the other near the centerline at

the after end of the cofferdam.

The controls for the eductor are located in a

watertight box on the pump room deck.

Two static-head liquid-level gages, or electronic

sensors, are installed in each cofferdam to indicate

the presence of leakage into the compartment. One is

located on the centerline in the forward end of the

cofferdam and the other on the centerline in the after

end. This arrangement makes it possible to determine

the presence of leakage, regardless of the trim of the

ship.

Access to the cofferdam is gained through a

bolted manhole cover in the pump room deck.

Normally, the cofferdam manhole cover is located

directly over the outer tank manhole cover.

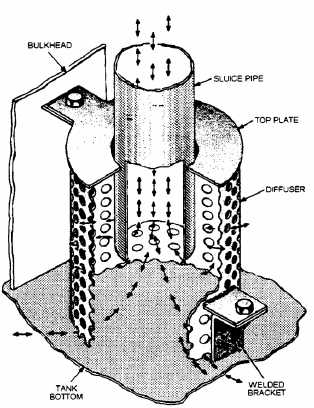

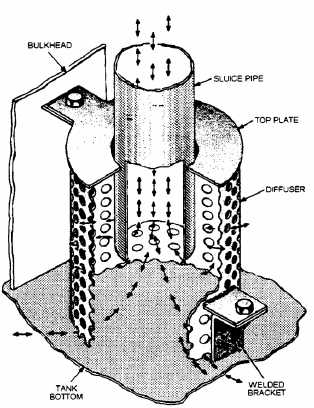

Storage Tank Diffuser

The diffuser (fig. 6-6) reduces turbulence when

gasoline or seawater enters the storage tanks.

Diffusers are mounted on the bottom of the gasoline

storage tanks around the end of each sluice pipe and

seawater supply riser. They are bolted to clips or

brackets that are welded to the bottom of the tank

and to the bulkhead.

The diffuser is a perforated cylinder with an

open bottom, and it has a top plate with an opening

for the gasoline or seawater supply pipe. The opening

in the top plate is larger than the outside diameter of

the supply pipe, which permits the pipe to move with

the movement of the ship’s structure. The total area

of the perforations in the diffuser is five times that of

the area of the supply pipe. Gasoline or water enters

the diffuser in a single stream and is broken into

smaller streams as it passes through the holes in the

cylinder. The distribution of flow over a large area

reduces turbulence.

Gaging Equipment

Two different types of gages are currently used

in the gasoline tanks to determine the amount of

gasoline within the tanks. These gages are the water-

filled, static-head type, and the TLI.

Figure 6-6.—MOGAS storage tank diffuser.

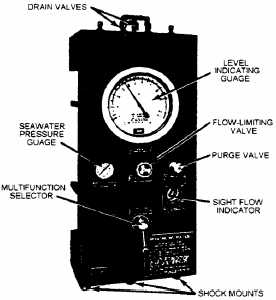

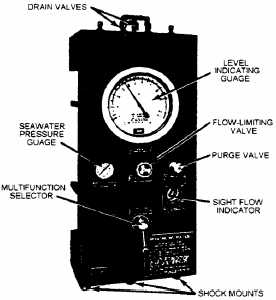

The water-filled, static-head gasoline gage (figs.

6-7 and 6-8) provides an accurate means of

determining the amount of gasoline in the saddle-type

storage tanks. It accomplishes this task by sensing the

differential created, as the plane of cleavage between

Figure 6-7.—Level indicating panel (front view).

6-8