nickel and carries the fuel. The outer pipe is steel and

serves as an armor casing. The outer pipe also serves

to contain a protective jacket of inert nitrogen gas at

3 psi around the inner piping. A pressure gage for the

double-walled piping is installed in the pump room to

indicate the pressure in the piping. The gage has a

range of zero to 15 psi.

If the outer casing is pierced, the nitrogen gas will

leak out. The resulting drop in pressure will be indicated

on the gage. Also, if a rupture should occur in the fuel

line inside the steel casing, the resulting increase in

pressure will be indicated on the gage. Isolate the piping

until the cause has been determined.

Expansion bellows are provided in the outer

casing to avoid strains in the casing due to unequal

expansion, which may result in leakage of the

nitrogen gas. Drain plugs in the bellows can be used

to determine whether any leaks have occurred in the

inner piping. Brass liners soldered to the outside of

the inner piping and steel spacers welded to the

inside of the outer piping are placed at intervals of

about 5 feet. These serve to hold the inner piping in

the center of the outer piping and still allow for

movement caused by expansion and contraction

between the two pipes. The outside piping is about 2

inches larger than the inner piping.

An inert gas connection, for charging the outer

piping, is provided at the lower or inboard end of the

double-walled piping. The outer piping is also

provided with a relief valve to avoid excess pressure.

The released inert gas is vented to the atmosphere

through separate piping. The relief valve is set at 15

psi.

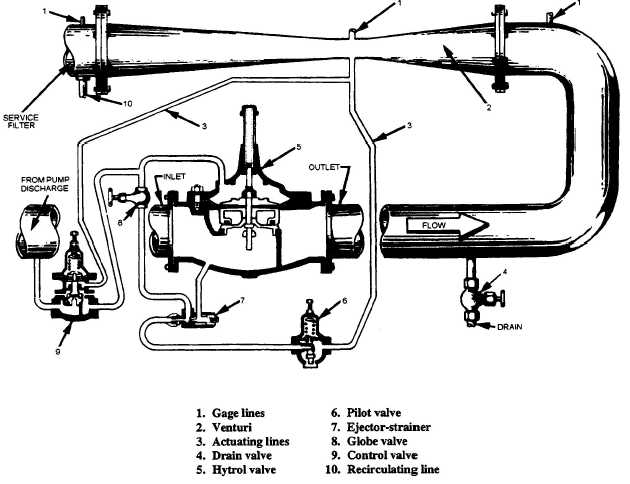

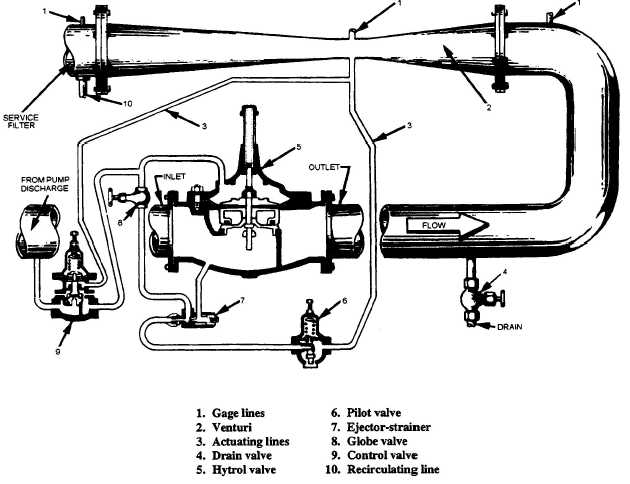

AUTOMATIC PRESSURE-

REGULATING SYSTEM

The pressure-regulating system (fig. 6-12) used in

MOGAS risers is identical for all class ships except for

size and pressure settings. This section deals with a

typical regulating system without reference to size

Figure 6-12.—MOGAS pressure-regulating system.

6-12