The procedure outlined above will establish the

desired downstream pressure and provide the correct

setting of the control valve.

Maintenance

The ejector strainer assembly should be cleaned

at regular intervals in accordance with PMS

requirements. Remove the 3/4-inch union ring and

plug from the housing, wash in solvent, and then

blow the screen out with air. At 6-month intervals,

the regulating valve should be completely dismantled

and thoroughly cleaned. The pilot valve and control

valve should be inspected carefully for excessive

wear, and, if necessary, replaced. All gages used in

the pressure-regulating valve system are removed,

cleaned, and calibrated every 12 months. Upon

installation of new parts or repairs made on parts, all

piping connections are pressure tested to check for

leakage of fuel.

MOGAS PUMPS

The MOGAS pumps on LPHs are centrifugal

pumps with a rated capacity of 50 gpm at 90 psi.

MOGAS pumps are typically called transfer

pumps. See chapter 4 for information of centrifugal

pumps.

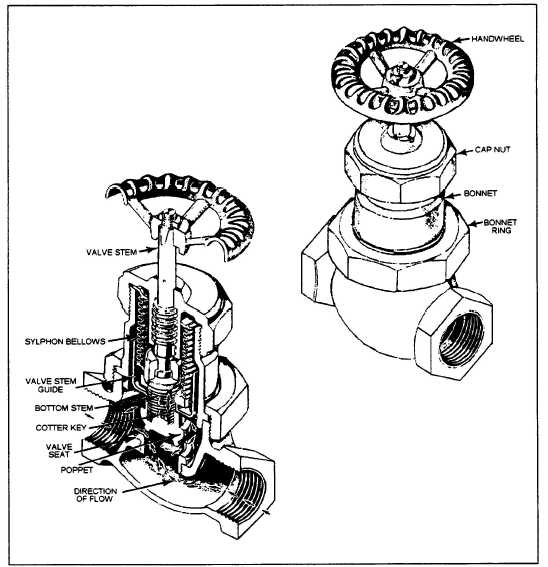

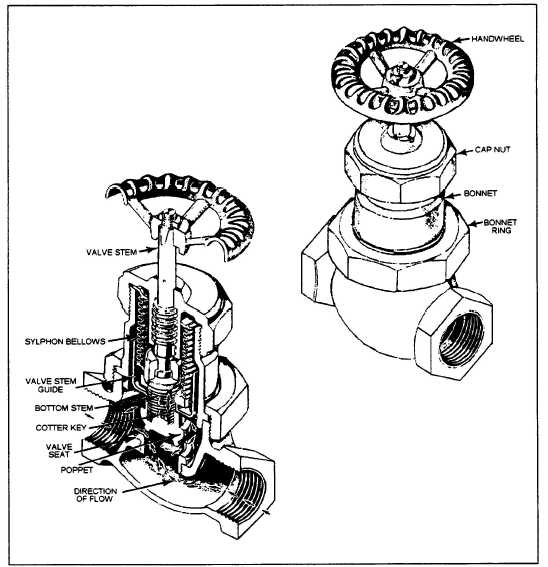

SYLPHON PACKLESS

GLOBE VALVE

The Sylphon packless globe valve (fig. 6-13) is used

to stop the hazardous leakage of gasoline past the

Figure 6-13.—Sylphon packless globe valve.

6-15