the third deck level. The height and size of the

overflow loop act as a relief device. It limits the

pressure that can be exerted on the tanks (within the

maximum allowable limits) when maximum pump

capacity is discharged overboard. This would be the

condition when the delivery of gasoline is stopped and

the seawater pump continues to operate. However,

the height of the loop and the expansion tank also

maintains an adequate back pressure on the tanks to

force gasoline to the suction side of the gasoline

pumps. This ensures a positive pressure (0.5 to 1 psi)

is maintained when maximum delivery of gasoline is

being made. A one-way check valve and a shutoff

valve are installed near the end of the overflow line.

The shutoff valve is normally LOCKED OPEN.

Steam-heating coils are installed around the overflow

line at the shell connection to keep the line clear

during icing conditions.

A vent line extends from the top of the loop to

the atmosphere at the 02 level. The vent line is

provided to break the syphoning effect of the overflow

loop to prevent lowering the pressure at the gasoline

pump suction header. This line also may be equipped

with steam-heating coils.

OPERATION OF THE

SEAWATER SYSTEM

The seawater system serves to force the gasoline

through the tank and up to the gasoline pump

suction. A pressure of about 0.5 to 1 psi is required at

the gasoline pump suction to prevent the gasoline

pumps from becoming vapor locked.

The seawater pump should be put into operation

before starting up the gasoline pump. The seawater

pump will discharge to the outer tank. As gasoline is

drawn from the tank, it is automatically replaced

with seawater, thus maintaining a positive pressure

on the gasoline pump suctions. Excess seawater will

automatically be discharged overboard through the

over-flow line.

1. To line up the system to take suction from the

sea and to discharge to the outer tank supply riser,

take the following actions:

a. Open the shutoff valve between the sea

chest supply riser and the pump suction header.

b. Open the shutoff valve between the pump

discharge header and the outer tank supply riser.

2. To align the seawater pump, take the

following actions:

a. Open the shutoff valve in the pump

suction line.

b. Vent the pump through a petcock at the

top of the pump casing. When seawater appears, close

the petcock.

c. Start the pump with the discharge valve

closed. When the pump discharge pressure builds up,

open the discharge valve SLOWLY.

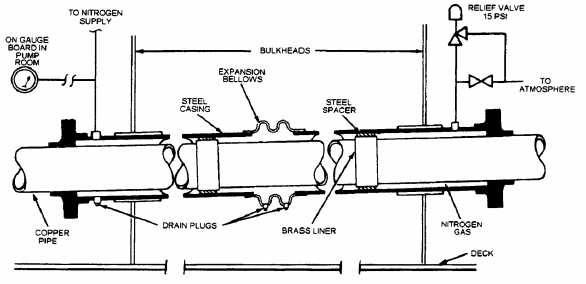

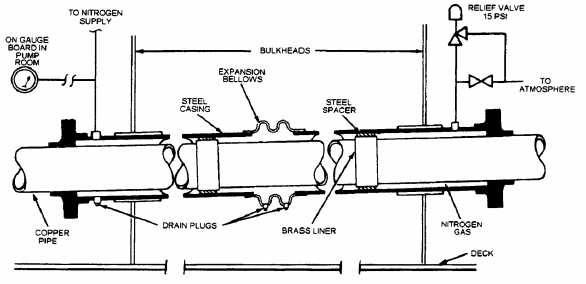

DOUBLE-WALLED

GASOLINE PIPING

When MOGAS passes through spaces, it is

carried in double-walled piping that consists of two

concentric pipes (fig. 6-11). The inner pipe is copper

Figure 6-11.—Double-walled piping.

6-11