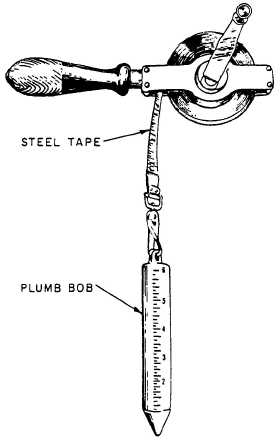

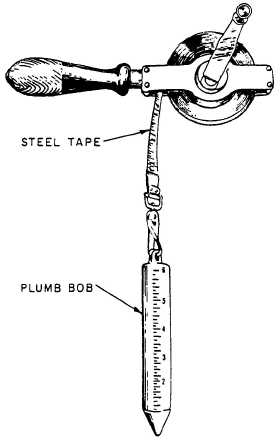

Figure 4-49.—Sounding tape.

Sounding Procedure

Spread a thin coating of water-indicating paste

from the tip of the plumb bob to about the 2-foot mark

on the tape. Lower the plumb bob through the

sounding tube until, it touches the striker plate. The

tape must be kept taut because slack would cause an

inaccurate reading. Slowly withdraw the tape. The

highest level where the JP-5 “wets” the tape is read

in feet and inches. If the “wet” mark is difficult to see,

use fuel-indicating paste. Dry the tape and spread a

thin coating of the fuel-indicating paste in the

approximate area of the first “wet” mark. When the

tape is removed, note the line of color change on the

fuel-indicating paste. This reading is then converted

to gallons by use of a tank capacity chart. When the

plumb bob is removed, note the line of color change of

the water-indicating paste. The normal color, when

applied, is gray. This level, in feet and inches, is

converted to gallons and subtracted from the JP-5

reading to determine the quantity of JP-5 in the tank.

Figure 4-50.—Thief samplers.

NOTE

The water-indicating and fuel-indicating

pastes are different colors. They also change

into

different

colors.

They

are

NOT

interchangeable.

To obtain a sample from the very bottom of the

tank, remove the plumb bob and attach the type-B

sampler shown in figure 4-50. Lower the sampler into

the sounding tube. (The distance from the sounding

tube cap to the striker plate will have been

determined during sounding operations.) As the tip of

the valve disk guide touches the striker plate, it will

be depressed by the weight of the sampler, raising

both upper and lower disks off their seat. After

retaining this position momentarily, retract the

sampler and dump the contents into a clean jar.

If water droplets or discoloration are noted on

the sounding tape during the sounding and bottom

sampling procedure, it is an indication of entrained or

free

4-61