movement caused by sloshing in the tank, a capacitor

is connected across the indicating meter to delay the

response (normally 3/4 second) of the meter to the

transmitter signal.

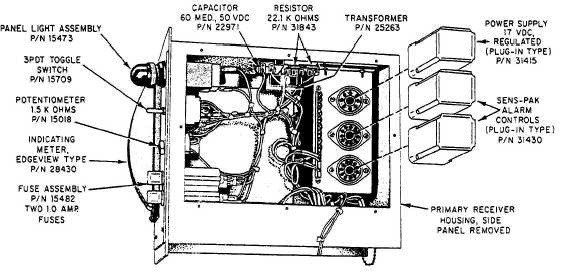

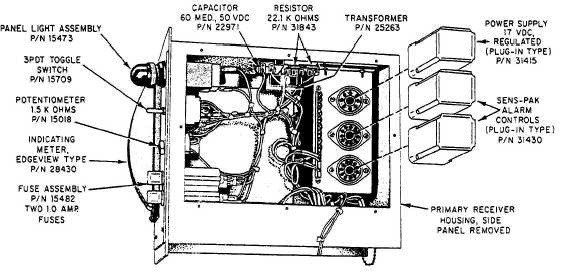

ALARM CONTROL SYSTEMS. Known as a

SENS-PAK alarm, its controls function integrally

with the tank level indication system to sense high,

low, or intermediate levels of tank liquids (as

appropriate) and actuates an alarm. The modular,

plug-in SENS-PAK units (fig. 4-47) are actuated by

voltage

signals

from

the

indicating

system

transmitter. These units may or may not be included

in the primary receivers.

Although all primary receivers are prewired for

a maximum of two SENS-PAK units, normally used

for high and low level alarms, additional control units

may be incorporated in separate housings within the

same system on advice from the factory.

SENS-PAK alarm control adjustments are

located on the side of the receiver (refer to figure 4-46

[side panel]) and function as follows:

Normal simulate switch—Substitutes the float

simulator circuit for the transmitter in the indicating

meter circuit for alarm adjustment.

Float simulator potentiometer—Simulates the to-

tal transmitter voltage divider resistance change over

the full range of float travel.

High alarm potentiometer—Sets the actuation

voltage level of the high alarm SENS PAK.

Low alarm potentiometer—Sets the actuation

voltage level of the low alarm SENS PAK.

This system surpasses the 3% accuracy

requirement of military specifications. But, the

accuracy will vary depending on the size tank being

gaged and the type receiver used.

NOTE

The Gems TLI systems are also approved for

indicating the interface level of two liquids

having different specific gravities.

With the ON-OFF-FULL REF. toggle switch on

the primary receiver in the ON position, operation of

the system, and alarms if included, is completely

automatic. Tank liquid level is read directly from the

indicating meter on the primary or secondary

receiver as required. No further attention is

necessary, as the Gems TLI system can operate

indefinitely without any component degradation.

The only maintenance that should be required is

cleaning of the transmitter and float when tanks are

opened for inspection and cleaning.

CONSOLES

The control console ushered in the modem era

for the ABF. It provides us with the ability to control

and monitor nearly all operations from one central

location. While the console relieves you of a lot of foot-

work, it requires an in-depth knowledge of your ship’s

systems and capabilities.

Each console (fig. 4-48) consists of a control panel

with

a

mimic

diagram,

various

selector

Figure 4-47.—Primary receiver interior.

4-56