the large overflow line and the arrangement of the

vent line. In addition to serving as a regular storage

tank, they are also designed to receive the overflow

from the other storage tanks in their respective nest.

The overflow tanks are actually a safety feature

to prevent rupturing of storage tanks if they are over-

pressurized during a filling operation. The overflow

tanks overflow overboard when they are full. The

large overflow line extends up from the top of the

tank to just below the second deck. Here it loops back

down and discharges into an overflow box on the

third deck. The overflow box contains a flapper check

valve that allows JP-5 to be discharged overboard but

prevents seawater from entering the tanks. An

inspection plate located directly over the valve allows

access for cleaning and maintenance. In the past,

flapper check valves have frozen open due to

corrosion, and seawater contamination of JP-5 has

resulted. These valves must. therefore, be inspected

at least every 6 months (more often if necessary).

The overflow tanks are vented via an air escape

riser from the top of the loop in the overflow line to

one of the common air escape mains. Overflow tanks

are the last tanks to be filled when receiving JP-5

aboard and are the first tanks to be emptied when

transferring internally.

Contaminated-JP-5

Settling Tanks

The contaminated-JP-5 settling tanks are

designated tanks that receive JP-5 from hose

flushings, defuels, tank stripping operations, and the

initial flow during a refueling at sea. In addition to

standard piping, these tanks have piping branching

from the defuel mains. Each branch of defuel piping

going into a contaminated settling tank must

terminate about 48 inches above the bottom of the

tank, with a perforated horizontal run about 24

inches long to reduce turbulence.

After stripping, JP-5 transferred from these

tanks will be transferred via a JP-5 reclamation

prefilter and JP-5 reclamation filter/separator, in that

order, to the storage tank manifold of the selected

storage tank to be filled.

JP-5 Service Tanks

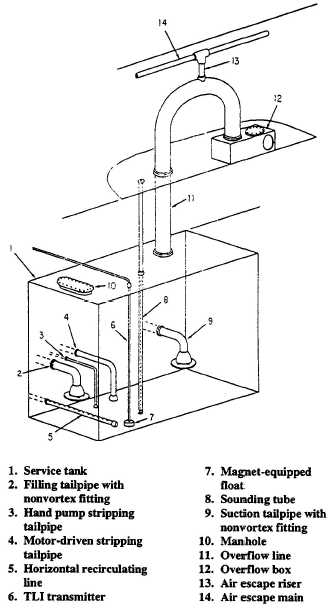

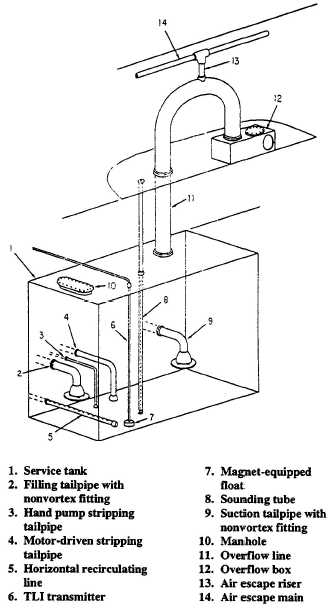

Although much of the equipment in the service

tanks (fig. 4-43) is similar to that described in the

storage and overflow tanks, the piping arrangement

is different and additional equipment is required.

Figure 4-43.—Typical JP-5 service tank.

Service tanks have an independent filling

tailpipe and an independent suction tailpipe. The

filling tailpipe branches from the service tank fill line

header in the JP-5 pump room to terminate in a non-

vortex bellmouth fitting between 6 to 24-inches off

the tank bottom. Additionally, the termination height

will beat least 3 inches lower than the suction

tailpipe. Service tanks are NEVER filled directly from

a tanker, barge, or pier. They are always filled from

settled storage tanks, via the centrifugal purifiers.

The suction tailpipe extends from the service

pumps common suction header to terminate in a non-

vortex bellmouth fitting either 12 or 24-inches off the

tank bottom in the opposite end from the fill line.

4-52