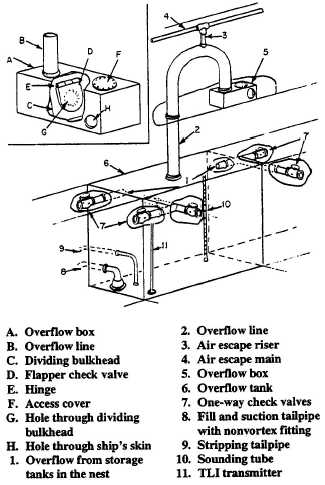

The air escape riser (vent line) prevents a

buildup of pressure when the tanks are being filled

and prevents a vacuum from forming when the tanks

are being emptied.

There are usually four air escape mains serving

the forward and after groups of tanks: two forward

(one port and one starboard) and two aft (one port

and one starboard). A cane-shaped vent line extends

up from each main to just below the 02 level and

loops back down to just below the 01 level, where it

terminates in scan. One end of the can, which

contains a flame arrester, penetrates the skin of the

ship and is open to the atmosphere. The outboard end

is covered with a ratproof screen, and the inboard end

is closed by an inspection plate. The flame arrester is

cleaned quarterly.

CAUTION

The ship’s side cleaners should be cautioned

about spray painting near these vents. Sprayed

paint can stop the flow of air through the vents

by clogging the flame arrester.

An overflow line extends from near the top of the

storage tank to an overflow tank. This line is

considerably larger than the tank fill line to prevent

rupture of the storage tank in the event of overfilling

at high pressure. When the tank is full, it will

overflow via a one-way check valve into the overflow

tank for that nest of tanks.

NOTE

A nest of tanks is that small unit of tanks

within a group of tanks that is serviced by one

overflow tank. The forward and after groups of

storage tanks consist of several nests of tanks.

A bolted manhole cover provides access to the

tank for inspection, cleaning, and maintenance. A

sounding tube extends from the extreme bottom of

the tank to the second or third deck. The lower end is

secured to a striker plate, and the upper end is closed

by a threaded access cap. That section of the

sounding tube within the tank has evenly spaced

holes to ensure that the level of fuel in the tube is the

same as that in the tank. Sounding tubes are

provided for measuring the quantity of JP-5 in the

tank, detecting water, and thieving a sample.

The suction and fill tailpipe extends from the

manifold to terminate between 6 to 24 inches off the

bottom at the lowest end of the tank. A nonvortex

bellmouthed fitting and a splash plate are installed

on the end of the tailpipe. This fitting reduces

turbulence when filling, prevents a vortex from

forming when emptying the tank, and prevents

taking a suction directly off the bottom. Storage tanks

are filled and emptied through this line.

The stripping tailpipe is similar in design to the

suction and fill tailpipe except it is smaller and has

no splash plate. This line extends from the stripping

manifold to a maximum of 1 1/2 inches off the bottom

at the lowest end of the tank. The stripping tailpipe is

used to remove water and sludge from the bottom of

the tank and to completely empty the tank by

removing the last 24 inches of usable JP-5 when

consolidating the fuel load. The stripping tailpipe is

also used when ballasting and deballasting the

storage tanks.

NOTE

JP-5 storage tanks have a filling rate of 500

gpm per tank, with the required minimum of

six tanks on the line.

JP-5 Overflow Tanks

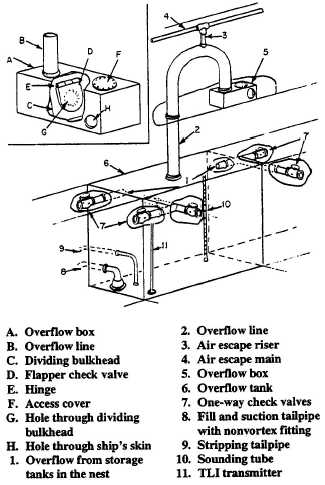

Overflow tanks (fig. 4-42) have the same fittings

previously described for the storage tanks, except for

Figure 4-42.—Typical JP-5 overflow tank.

4-51