has been filled to about one-half inch from the

top.

WARNING

Do not use mouth suction to fill the

sampling tube. Many oils and fluids are

highly toxic and may cause paralysis or

death.

4. Replace the bottle cap and tighten it to

prevent leakage of the sample. Replace the cap

on the tank and discard the sampling tube.

5. Reduce the chance of misidentifying

samples by marking all oil samples with equip-

ment/system identification as soon as possible

after sampling.

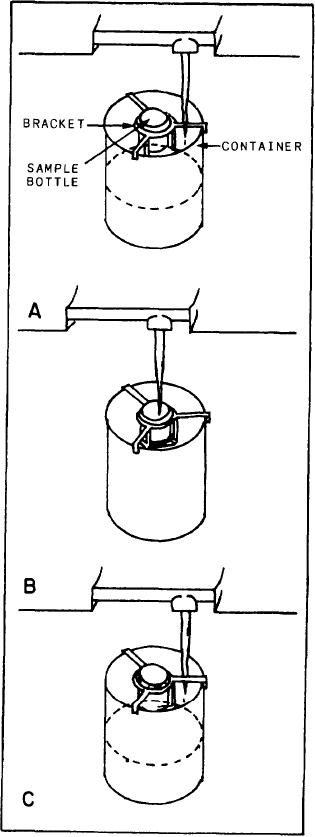

DRAIN SAMPLING.-- When using the drain

sampling method for getting a fluid sample, you

should use the following procedures:

1. Open the sample bottle.

2. Open the drain outlet in the bottom of the

tank, sump, case, or drain port, and allow enough

oil to flow through. This washes out accumulated

sediment. (See fig. 5-19, view A.)

3. Hold the sample bottle under the drain and

fill to about one-half inch from the top. (See

fig. 5-19, views B and C.) Close the drain outlet.

4. Replace the bottle cap and tighten it enough

to prevent leakage.

5. Reduce the chance of misidentifying

samples by marking all oil samples with equip-

ment/system identification as soon as possible

after sampling.

NOAP Forms and Logbook Entries

Activities are also responsible for completing

appropriate forms and making entries in the

equipment logbook.

Proper completion of the Oil Analysis Request

(DD Form 2026) is vital (fig. 5-20). Maintenance

actions or recommendations (table 5-4) are based

on information provided by this form and the oil

sample. Incomplete information (oil added since

last sample, hours since overhaul, etc.) could

result in an invalid oil analysis and recommenda-

tions. The operating activity must also provide

special reports or feedback information requested

by the oil analysis laboratory or the CFA.

Figure 5-19.-Oil drain sample technique.

Logbook entries are necessary when starting,

stopping, or changing the monitoring laboratory

for oil analysis. A specific notation is also made

5-24