Each operating activity participating in the

of that time specified. This requirement must be

NOAP must take routine samples properly

considered when equipment is scheduled for

and at the prescribed intervals. In addition to

detachments or missions away from the home

the routine samples, each operating activity is

base. Oil samples will still be due while away. The

required to submit special samples under the

customer (squadron or detachment) is responsible

following conditions:

for coordinating oil analysis support at mission

or transit site(s).

1. When samples are requested by the CFA

or by the laboratory.

NOTE: Refer to the applicable scheduled

maintenance or periodic inspection docu-

2. When the activity is so directed by the unit

ment for the specific routine sampling

maintenance officer to check out suspected

interval. Also look for specific sampling

deficiencies.

instructions for each type/model/series of

3. When abnormal conditions exist, such as

equipment being sampled.

malfunction of the oil lubricated part, damage to

the oil lubricating system, excessive engine oil loss,

or zero oil pressure.

4. Before and after the replacement of major

oil lubricating system parts.

5. During and at the completion of a test cell

run. If the repaired or suspect unit is operated on

oil previously used in the test cell system, a sample

must be taken. This is done before and after the

completion of the test cell run.

6. After the final test on an aircraft that is

undergoing rework or scheduled depot-level

maintenance or after installations of new/over-

hauled engines or engines repaired by AIMD.

7. Following all accidents, regardless of cause

and resulting damage. These samples must be

taken by any means possible to get a representative

sample.

There are two basic methods of taking a fluid

sample: (1) the dip tube technique, and (2) the

drain technique.

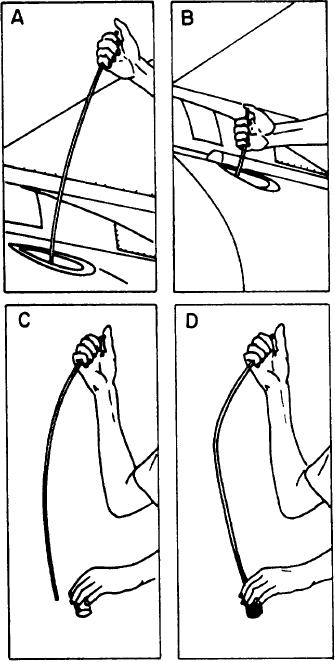

DIP TUBE SAMPLING.-- The following

procedures should be followed when using the dip

tube method for getting a fluid sample:

1. Remove the filler cap from the oil tank and

open the sample bottle.

2. Use a sampling tube of the correct length.

Hold the tube at one end and lower it into the

tank through the filler neck until only the upper

end protrudes. (See fig. 5-18, views A and B.)

3. Allow the lower end of the tube to fill with

oil, then close the upper end with your thumb or

finger. Withdraw the tube and drain the trapped

oil into the sample bottle. (See fig. 5-18, views

C and D.) Repeat this operation until the bottle

Figure 5-18.-Dip tube oil sampling.

5-23