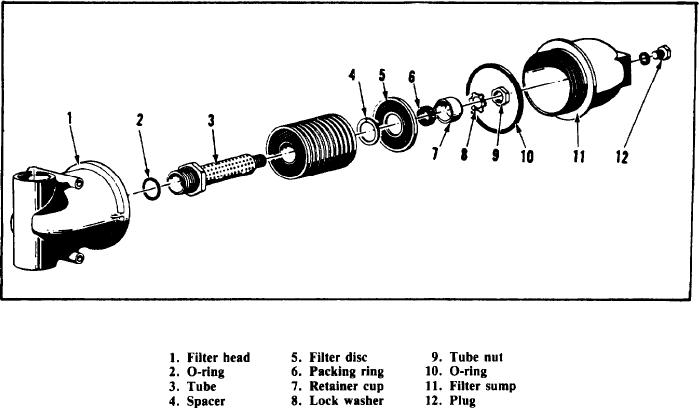

Wafer Screen Filter

operation of the aircraft engine. The engine-driven

fuel pumps must be capable of delivering the

maximum needed flow at high pressure to obtain

The wafer screen filter, shown in figure 4-25,

satisfactory nozzle spray and accurate fuel

has a replacement element made of layers of

regulation.

screen discs of bronze, brass, and steel. This type

of filter can remove minute particles. It also has

the strength to withstand high pressure.

Fuel pumps for engines are generally positive

displacement gear, piston, or rotary vane types.

The term positive displacement means that the

Plain Screen Mesh Filter

pump will supply a fixed quantity of fuel to the

engine.

The plain screen mesh filter is the most

These pump types may be divided into two

common type. It has long been used in internal-

combustion engines of all types for fuel and oil

groups--constant displacement and variable

strainers. In present-day turbojet engines, it is

displacement. Their use depends on the fuel

used in units where filtering action is not so

control system used to regulate the flow of fuel

critical, such as in fuel lines before the high-

to the fuel controls.

pressure pump filters. The mesh size of this type

of filter varies greatly according to the purpose

Gear-Type Pumps

for which it is used.

Gear-type pumps have straight-line flow

ENGINE-DRIVEN PUMPS

characteristics. However, fuel requirements vary

with flight or ambient air conditions. Hence, a

Engine-driven fuel pumps deliver a continuous

pump of adequate capacity at all engine operating

conditions will have excess capacity over most of

supply of fuel at the proper pressure during

Figure 4-25.-Wafer screen filter.

4-28