time. It is very important that the fuel be evenly

typical combustion chamber drain valve is shown

distributed by the spray to prevent the formation

in figure 4-17.

of any hot spots in the combustion chambers. It

When the fuel collects in the drain lines, the

is of particular value for this reason that the spray

drain valve allows the fuel to drain when pressure

be well centered in the flame area of the liners.

in the combustion chamber manifold is reduced

Fuel nozzle types vary between engines; mostly

to near atmospheric pressure. As shown in figure

fuel is sprayed into the combustion area under

4-17, the drain valve is spring-loaded in an open

pressure through small orifices in the nozzles. The

position. It is closed as pressure within the

nozzles generally used are of the vaporizing orifice

manifold and lines to the burners increases above

type and include the simplex and the duplex

that of the spring tension trying to keep the valve

configurations. The duplex nozzle usually requires

open. It is imperative this valve be in good work-

a dual manifold and a pressurizing valve or flow

ing condition to drain accumulated fuel after each

divider. This is to divide primary and secondary

shutdown. Otherwise, a HOT START during the

(main) fuel flow, while the simplex nozzle requires

next starting attempt or an AFTERFIRE after

only a single manifold for proper fuel delivery.

shutdown may occur.

Fuel Spray Nozzles and Fuel Manifolds

SIMPLEX FUEL NOZZLE.-- The simplex

fuel nozzle was the first type of nozzle used in

In jet engines, the fuel spray nozzles function

turbojet engines, but it was replaced in most

is to inject fuel into the combustion area in a

installations with the duplex nozzle, which gives

highly atomized, precisely patterned spray. It then

better atomization at starting and idling speeds.

burns evenly and in the shortest possible space and

The simplex nozzle is still being used to a limited

degree. A simplex nozzle is shown in figure 4-19.

Each of the nozzles of the simplex type consists

of a nozzle tip, an insert, and a strainer made of

a fine-mesh screen and a support.

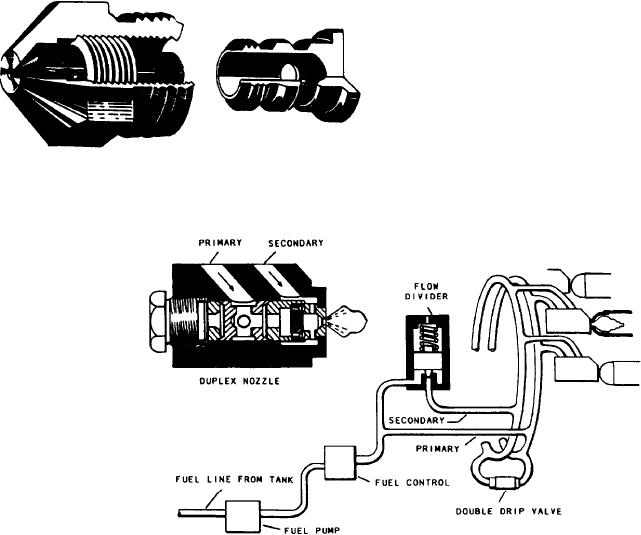

DUPLEX FUEL NOZZLE.-- The duplex fuel

nozzle is the type nozzle most widely used in

present-day engines. Its use requires a flow

divider, which gives a desirable pattern of spray

for combustion over a wide range of operating

pressures. A nozzle of this type is shown in

figure 4-20.

Figure 4-19.-Simplex fuel nozzle.

Figure 4-20.-Duplex fuel nozzle.

4-25