including stage, area, magnitude, direction, and

Establish internal reference points. Pictorial

adjacent material conditions. Some inspection

and cutaway diagrams help establish these

cards instruct you to mark or bend an 18-inch

reference points. When the probe is in the inspec-

length of lockwire, and then insert the wire

tion port, it is easy to lose your sense of direc-

through an adjacent inspection port. You can then

tion. Some borescopes have an index mark on the

use this wire as a gauge to measure vane cracks

eyepiece to show direction.

while viewing through the borescope.

Figures 9-17 and 9-18 show different engine

Scan the inspection area thoroughly and

parts seen through a borescope. You must know

in an orderly manner. Compressor cracks can be

the words to describe the damage found. Then

difficult to detect because of small close parts,

compare this information with serviceability

rotating the engine too fast, or because of

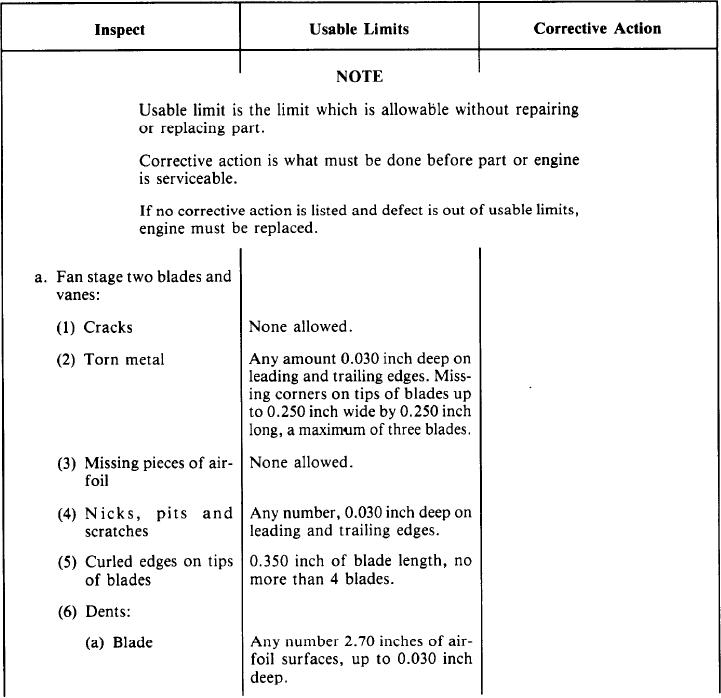

limits in the maintenance instruction manuals. See

deteriorated borescope optics. Note and evaluate

table 9-4.

any inconsistencies. Record all information,

Table 9-4.-Examples Of Serviceability Limits

9-21