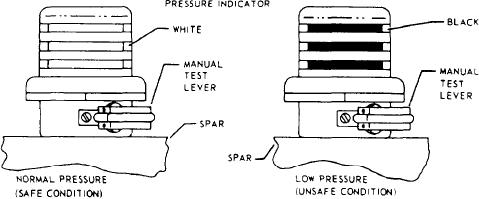

black that shows depends on pressure in the

blade has an air valve in the spar back wall near

s p a r . Remove from service any blade on

the root end and a cylindrical pressure plate. The

which the pressure indicator shows any black

root end plate is attached to the inboard end of

color. The blade may be put back into service

the spar. A seal plate is found inside the spar tip

when the unsafe (black) indication is found

end. Both are sealed for pressurization. Pressure

and corrected. Replace a malfunctioning in-

loss in the spar shows impaired integrity of the

dicator, but only if the spar pressure is within

spar or a seal leak. The cuff provides the means

permissible limits.

for attaching the blades to the rotary wing head

sleeve spindles. Nickel-plated or titanium abrasion

strips bonded to the spar leading edges prevent

erosion.

TAIL (ROTARY) RUDDER HEAD

Older blades consisted of a hollow extruded

The rotary rudder head provides for attach-

aluminum spar and aluminum pockets. They have

ment of the rotary rudder blades and counteracts

a tip cap, a root cap, and a steel cuff. Newer

the torque of the main rotor head. See figure 7-20.

blades consist of a pressurized titanium spar,

It also serves as a rudder for directional control

honeycomb core, and fiber glass graphite

of the helicopter. The rotary rudder head

skin. The newer blades are often repairable at

is driven by the tail gearbox. Blade pitch

organizational-level maintenance instead of depot

changes by the action of the pitch change

level. They are repairable at the lower level of

shaft. The pitch change shaft moves through

repair because of their honeycomb and fiberglass

design. Both types of blades are statically and

the center of the output gear shaft of the

tail gearbox. As the shaft moves outward

dynamically balanced to permit individual replace-

from the gearbox, the pitch of the blades

ment and interchangeability of the blades. In

decrease. The pitch beam is connected by

addition to balancing, manufacturers and depot

repair facilities stencil blades with a pretrack

adjustable pitch change links to the forked

number to aid in blade tracking.

brackets of the blade sleeves. The flapping

spindles permit flapping of the blades in each

direction.

The pressure indicator, usually known as

a BIM or a blade inspection method, compares

Tail rotor blades are built around a spar

built-in reference pressure with blade spar

that mounts on the tail rotor. The SH-3 has

pressure. See figure 7-19. When pressure

five all-metal, single aluminum pocket blades

in the spar is within the required service

bonded to a C-shaped spar. The SH-60 blades

limits, three white stripes show in the indicator.

are built around two graphite composite spars.

If pressure in the spar drops below the minimum

Honeycomb paddles are then bonded to the

permissible service pressure, the indicator will

spars with fiber glass to form the blade.

show three black stripes. The amount of

Figure 7-19.-Blade pressure indicator (BIM).

7-22